SWIR Cameras & Cores

SWIR cameras (short-wave infrared cameras) detect photons with wavelengths between 900 nm and 2500 nm. Short wave IR light interacts with objects similarly to visible light, as it is reflective; consequently, it exhibits shadows and contrasts in its imagery. As a result, images from SWIR cameras are comparable to visible images in terms of resolution and detail.

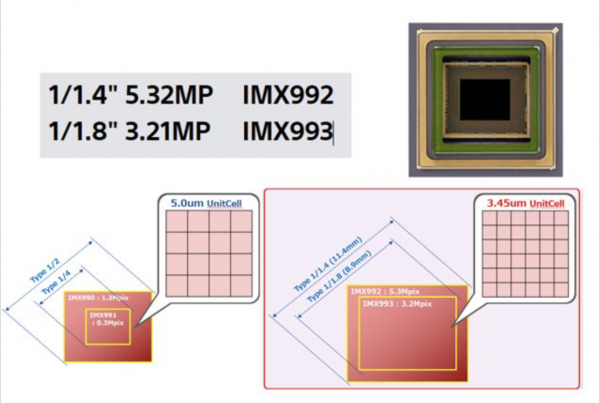

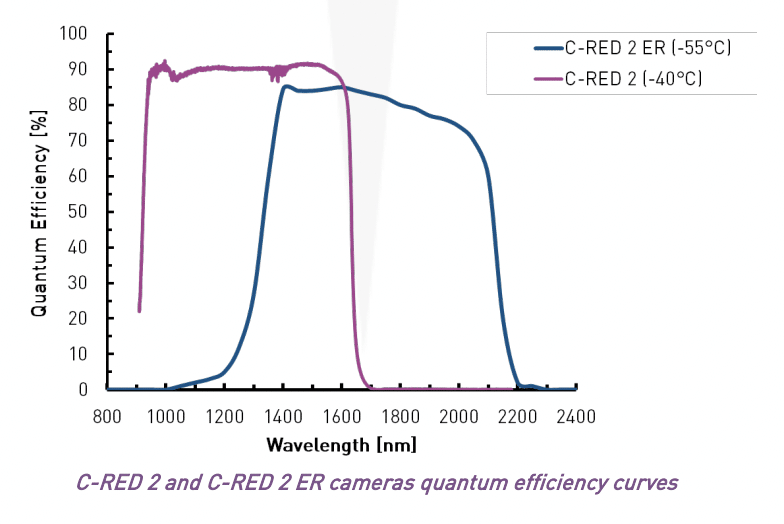

Because standard silicon-based sensors are typically sensitive up to 1000 nm only, SWIR cameras require sensors capable of imaging beyond the upper limit of silicon. InGaAs (indium gallium arsenide) sensors are conventionally used for SWIR imaging and cover the 900 nm to 1700 nm spectral range with high quantum efficiency (typically > 70%). Recent improvements to InGaAs sensors enable imaging both visible and SWIR (400 nm to 1700 nm using SenSWIR™ technology from Sony©, for example) or beyond the standard 1.7 µm cut-off with extended range solutions up to 2.2 µm.

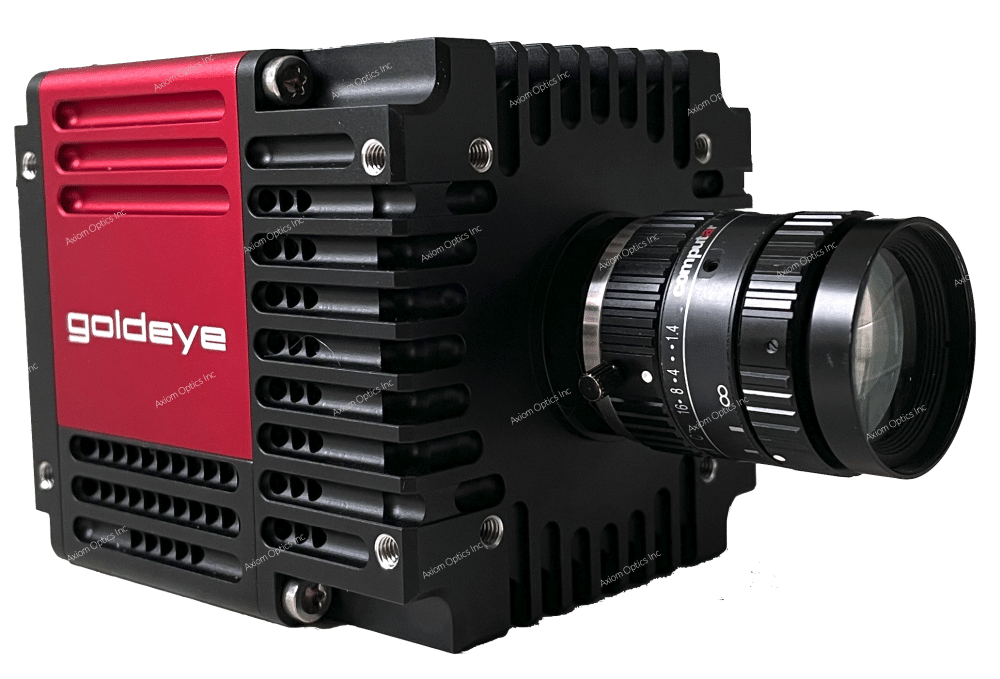

Axiom Optics supplies InGaAs SWIR cameras from industry-leading manufacturers. We can help you select the right camera for your intended application, thanks to our diverse portfolio. Our team is able to provide a solution for applications requiring high frame rate, high resolution with megapixel InGaAs sensors up to 5.3 MP (IMX992), small pixel pitch, high sensitivity, long exposure times, small form factor, and much more.

Extended range SWIR imaging

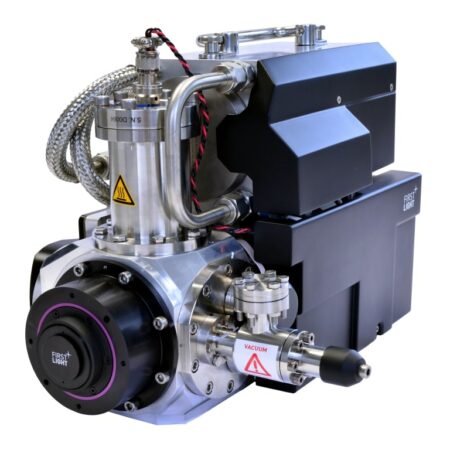

Extended range SWIR imaging FSO & AO

FSO & AO Long exposure times up to 2 min

Long exposure times up to 2 min