The Only 400-800 nm High Resolution Wavefront Sensor

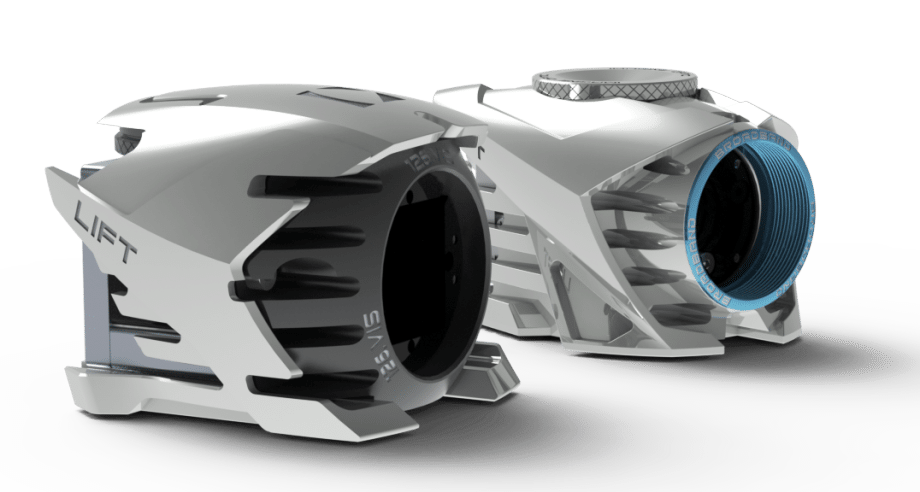

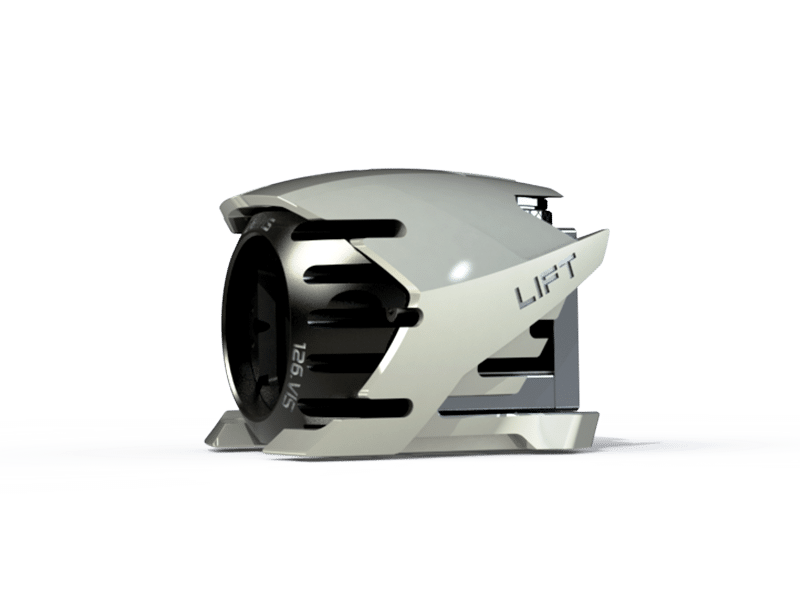

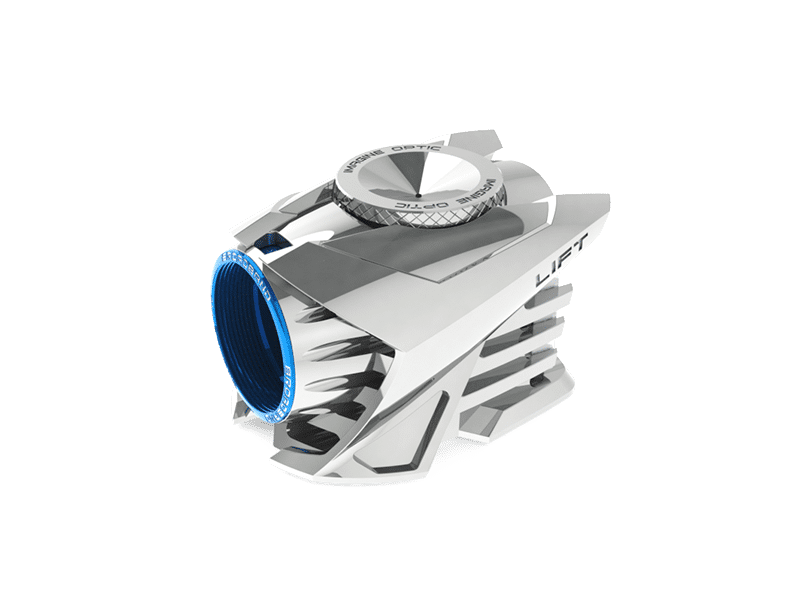

The HASO gets a 16-fold improvement in phase-point resolution by integrating Shack-Hartmann technology with a microlens-scale phase retrieval algorithm. Delivering exceptional performance, the HASO wavefront sensor family finds widespread application across the globe in challenging fields such as optical metrology, industrial control, microscopy, and laser diagnostics. Derived from the HASO 4 Broadband and HASO4 126 VIS design, the HASO LIFT high resolution wavefront sensors match their counterparts in accuracy and dynamic range while boasting an unparalleled resolution of 272 x 200 (LIFT 272) or 680 x 504 (LIFT 680) phase points. This unique capability enables the HASO LIFT to excel in applications from intricate optical systems to freeforms and metasurfaces that demand high accuracy, extensive dynamic range, and superior spatial resolution.

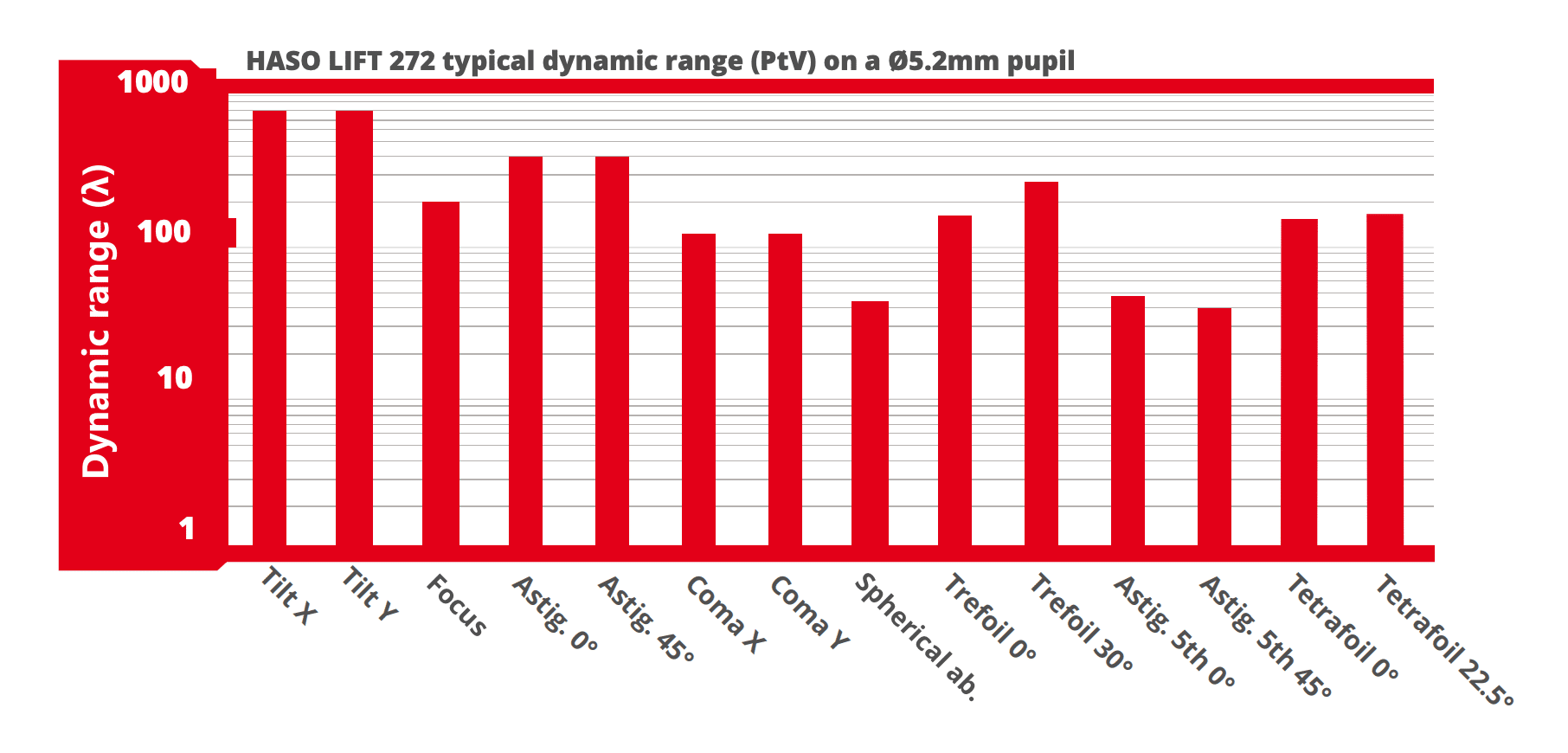

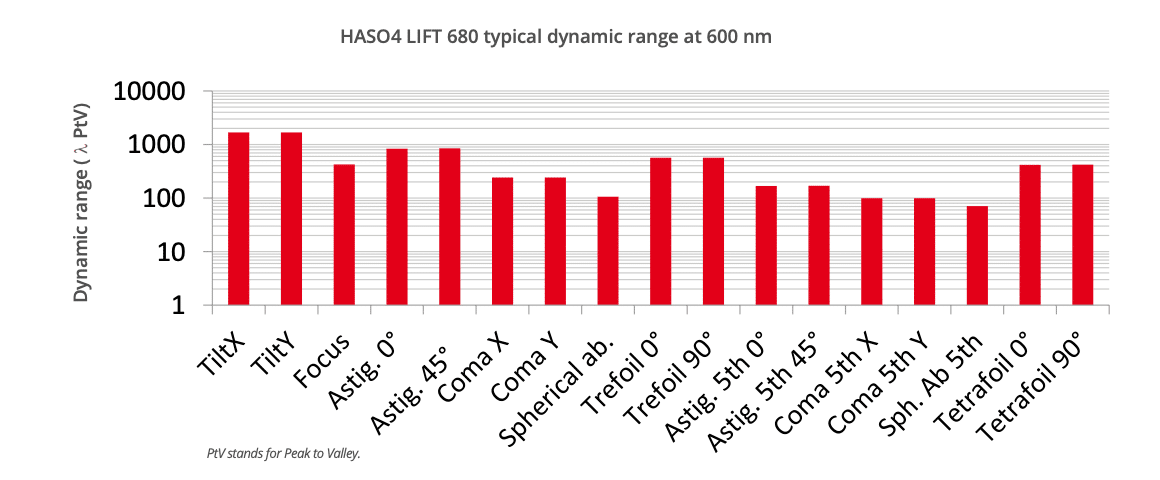

- λ/100 rms absolute accuracy on a huge dynamic range (see the graph below)

- 54 400 phase point resolution on 7.0 x 5.2 mm2 (LIFT 272) or 342 720 phase point resolution on 13.77 x 10.22 mm2 (LIFT 680)

- Measurement up to 64 Zernike polynomials with individual accuracy better than 1 nm RMS

- Spot Tracker provides easy HASO alignment and the capability to precisely follow absolute tilt/wavefront evolution over time

Best for Challenging Applications

- High spatial sampling frequency

- Very large dynamic range

- Freeform optics characterization

- Parabolic mirrors characterization

- High spatial frequency aberrations

16x Resolution Improvement with HASO LIFT Algorithm

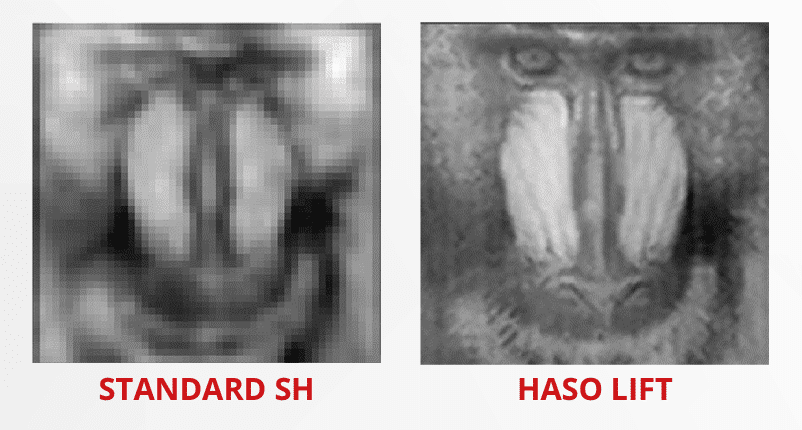

The HASO gets a 16-fold phase-point resolution enhancement by combining Shack-Hartmann technology with a phase retrieval algorithm applied at microlens scale.

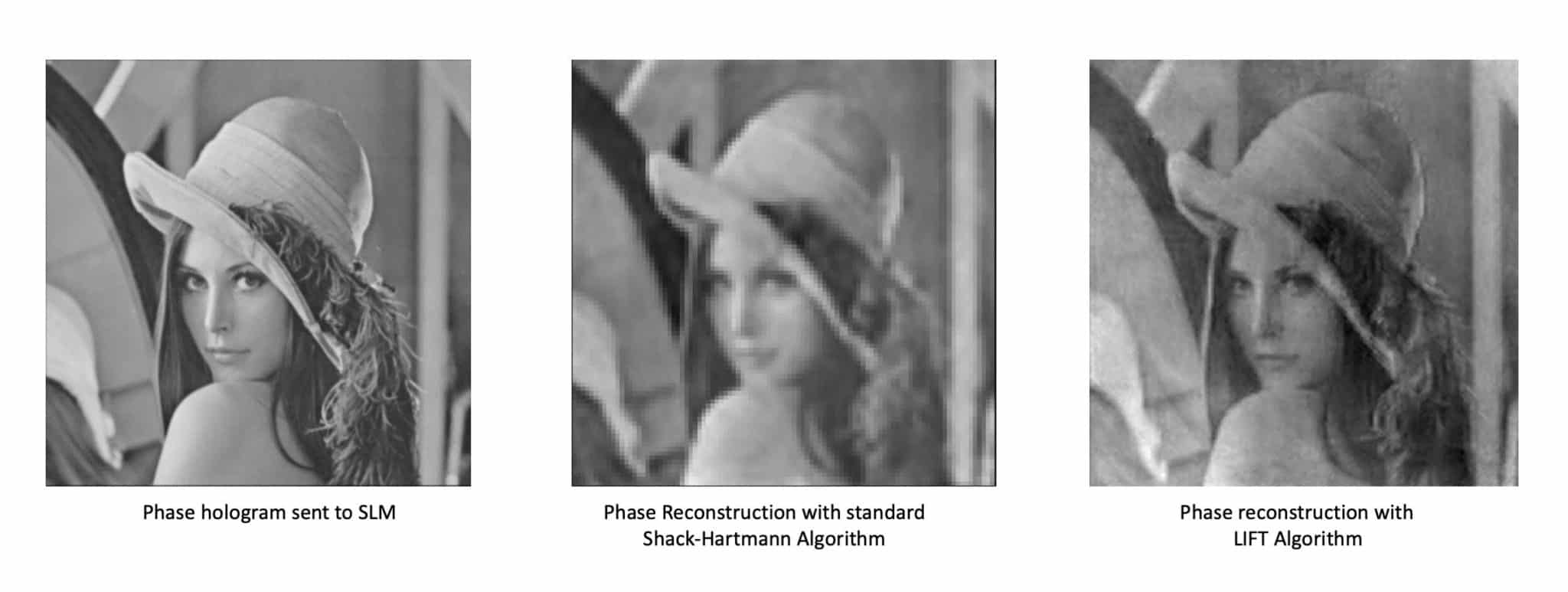

The presented images were captured within a characterization set-up, illustrating the enhanced resolution achieved through the implementation of the LIFT algorithm. A high-resolution phase image, produced by a Spatial Light Modulator (SLM), was transmitted to our wavefront sensor. The contrast between the results with and without the activation of the LIFT algorithm is remarkable. An in-depth study reveals a 16-fold increase in resolution, translating to a fourfold improvement in both the X and Y directions.

Transform your Wavefront Sensor into a full Metrology Solution with R-FLEX & R-FLEX LA

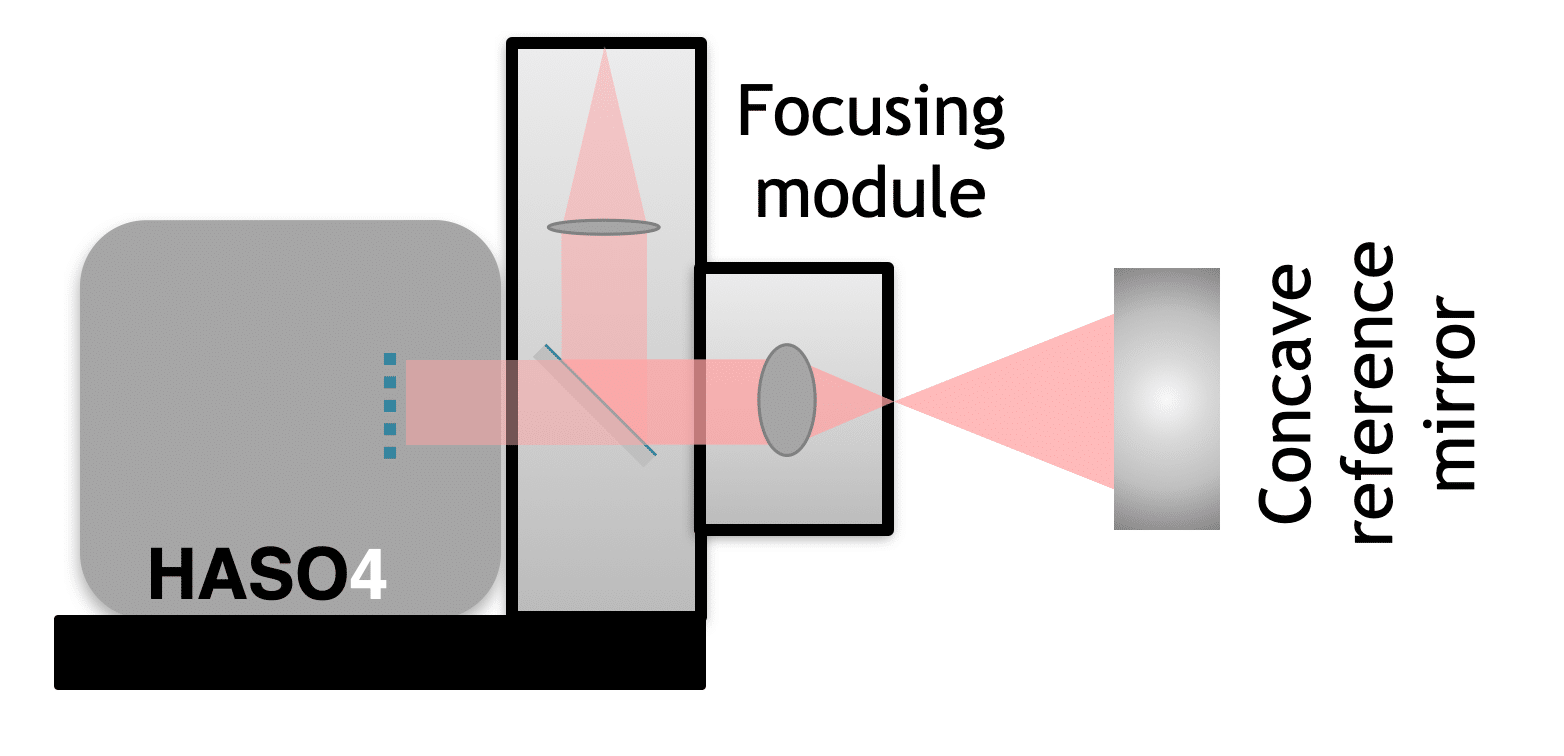

The R-FLEX2 stands out as a flexible optical metrology system seamlessly integrating any HASO4 wavefront sensors with a collimator and a light source. Presently employed in diverse applications, the R-FLEX2 plays a crucial role in quality control for life science instrumentation, alignment of large telescopes and collimators, as well as the assessment of large concave mirrors, lenses, and complex optical systems in general.

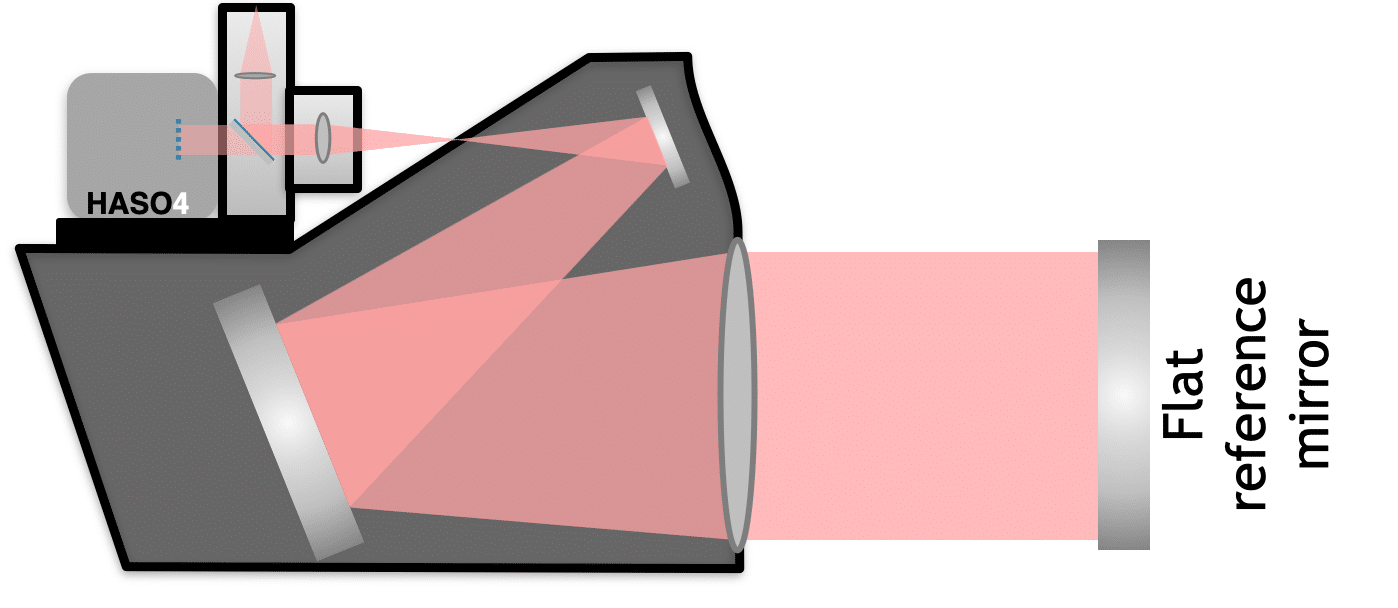

The R-FLEX LA serves as a collimating platform, expanding the functionalities of the HASO R-FLEX2 to encompass large optics and optical surfaces. The collimated beam produced by this platform varies in size, ranging from 30 to 150 mm. It is adept at analyzing extensive optical components such as filters, dichroic beam splitters, head-up displays, eyewear, optical windows, flat mirrors, and polarization scramblers.

Learn more about the R-FLEX2 LA

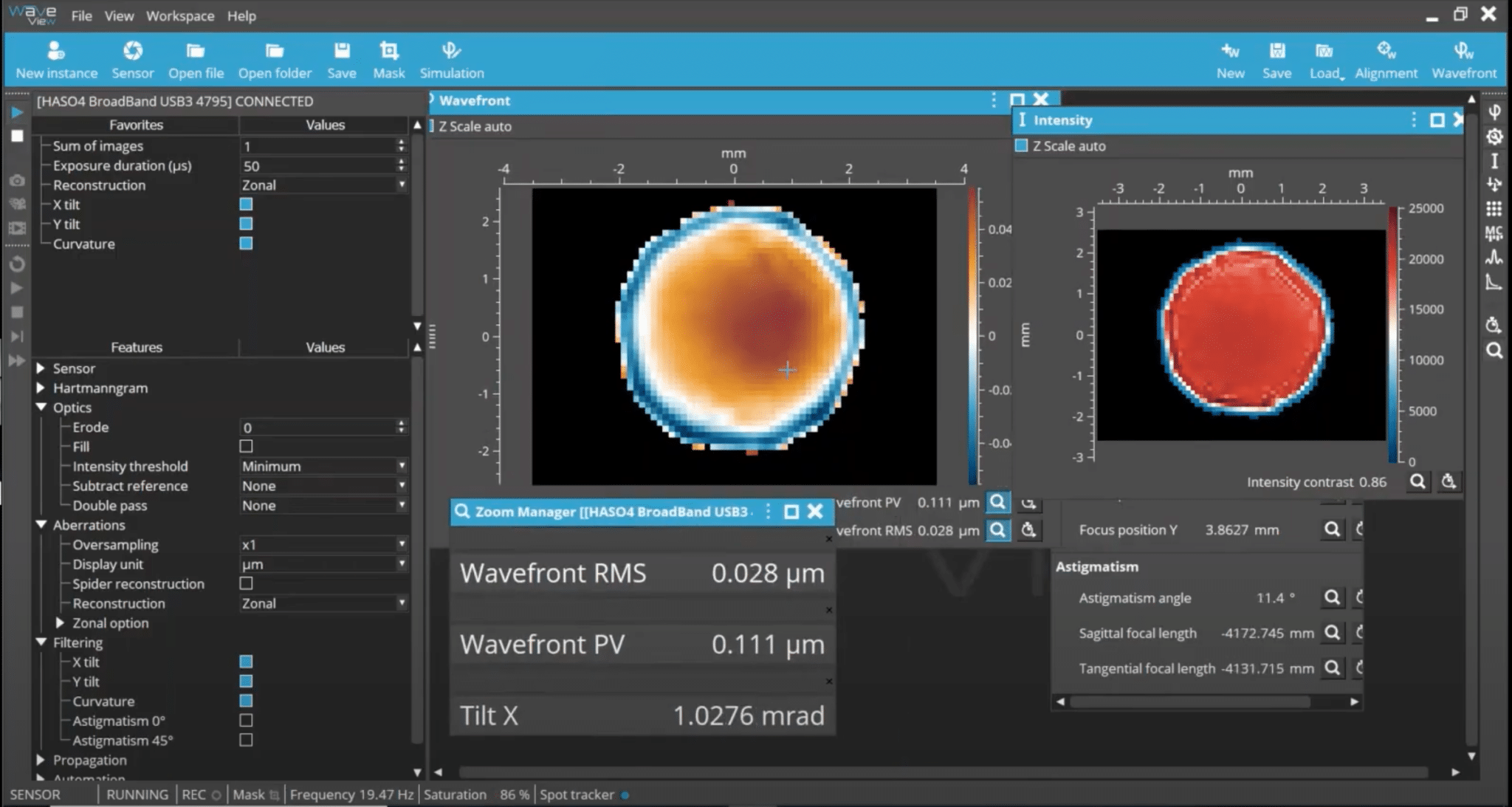

The Most Advanced Wavefront Measurement and Analysis Software

WaveView4 offers more than 150 features and tools optimized for a wide range of highly demanding applications. Its development philosophy is based on tens of years of customer’s feedback, improving the user experience with each version. Moreover, this software provides a function to analyze segmented wavefronts and allows autosave for sequence measurements. Modules dedicated to PSF, MTF, and M2 are available.

WaveKit is SDK in C/C++, LabVIEW and Python, providing the basic blocks on which one can build a fully customized software for specific HASO-based applications or WaveView4 data processing routines. It is available on request.

HASO LIFT Applications

- High spatial sampling frequency

- Very large dynamic range

- Freeform optics characterization

- Parabolic mirrors characterization

- High spatial frequency aberrations

Click here to learn more about Wavefront Sensing applications.