A new laser diagnostic tool offering instantaneous M squared measurement

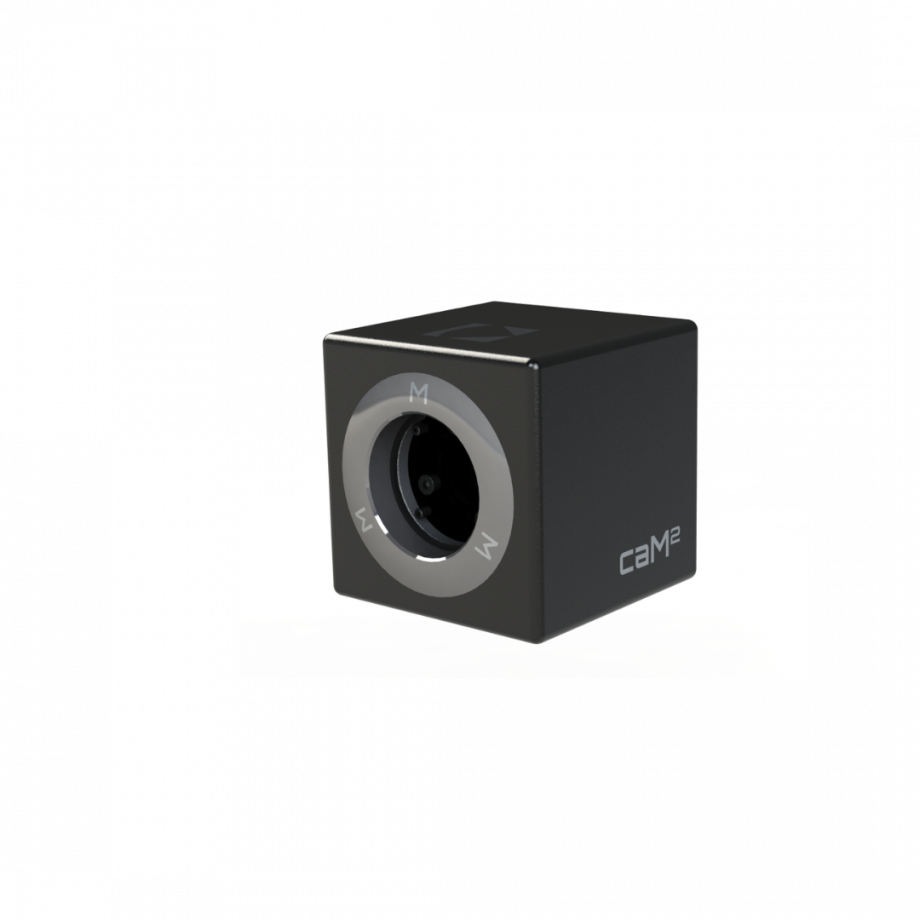

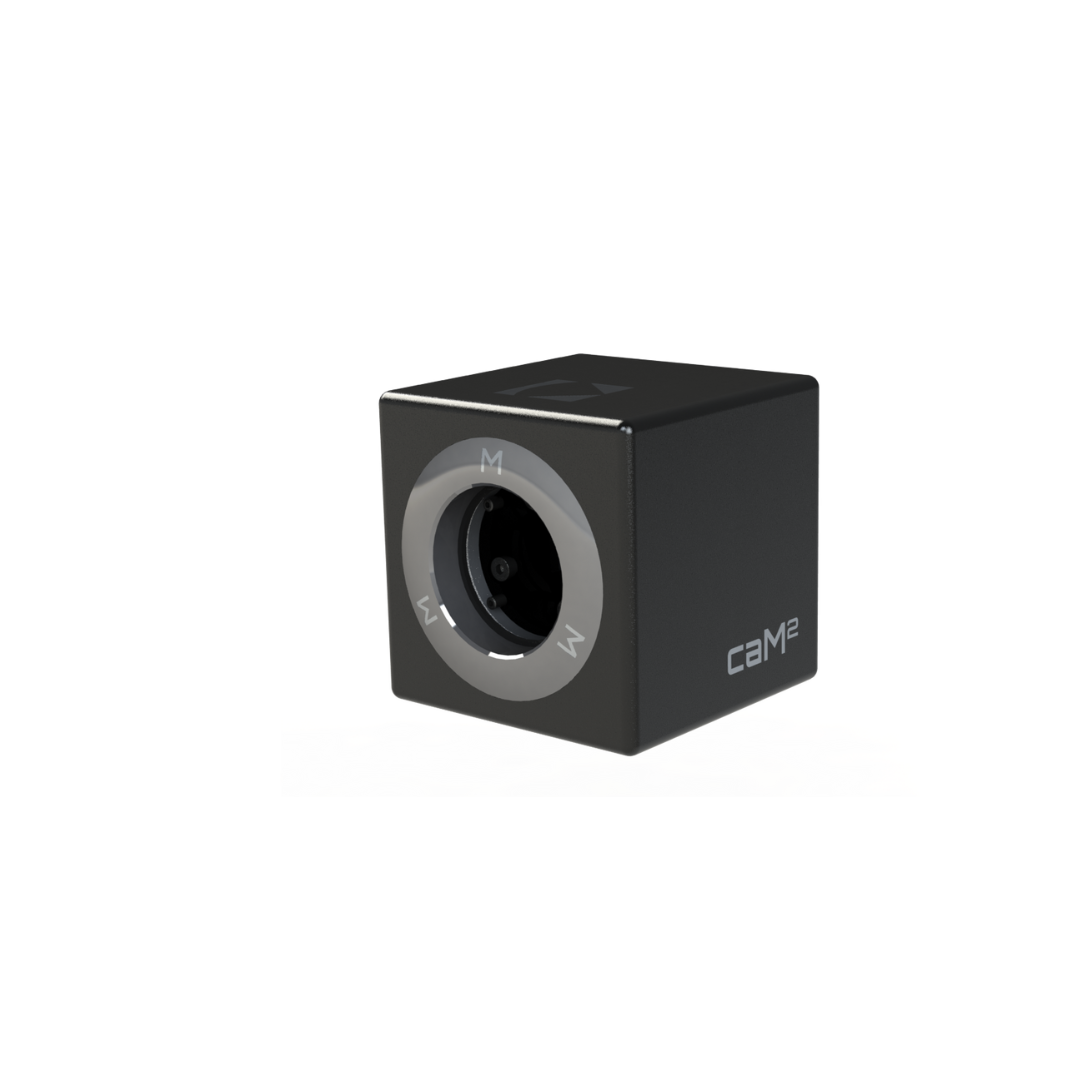

CAM SQUARED is an innovative and compact system designed for easy and fast M squared measurement. Based on wavefront sensing, CAM SQUARED fully characterizes your laser beam in compliance with standard ISO10116 norm. It provides a full list of parameters such as : M squared (M2) parameter, divergence, waist size and position, Rayleigh length, astigmatism and more. Unlike classical M2 measurement systems, CAM SQUARED has no moving parts (no translation stage), and requires very little to no alignment. Beam quality metrics are updated live in Waveview software at a rate of a few Hz , allowing the user to have quick feedback on their laser beam quality.

The video below shows an operator aligning a Cam Squared unit in a few seconds on a 532 nm beam. The M squared parameter refreshes every second.

Two versions of CAM SQUARED are available depending on your laser beam width, on the 350-1100 nm band:

- Size M (Medium) : pupil size= 4,5 x 3.7 mm² ; maximum frequency= 125 Hz (USB 3.0) or 30 Hz (GigE) ; beam diameter min. = 0.7 mm @ 1/e2, max. = 3 mm @ 1/e2

- Size L (Large) : pupil size= 6,9 x 5,1 mm² ; maximum frequency= 55 Hz (USB 3.0) or 30 Hz (GigE) ; beam diameter min = 0.7 mm @ 1/e2, max. = 4.2 mm @ 1/e2

A new M squared measurement method compliant with ISO11146 standard based on high accuracy Shack-Hartmann wavefront sensor

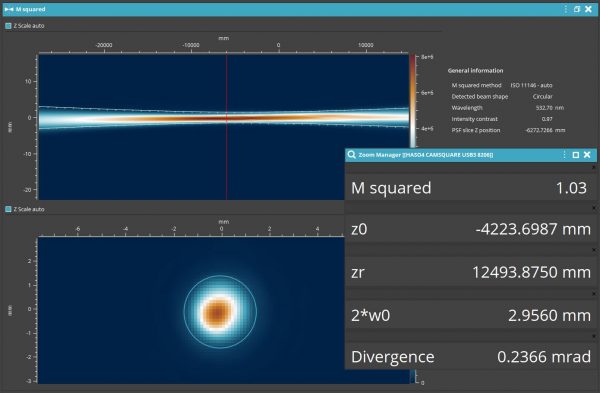

Based on feedback from laser manufacturers and its expertise in wavefront sensing, Imagine Optic developed a new method to measure the M squared based on high accuracy wavefront measurement and propagation. This new approach only requires a unique single snapshot performed with a Shack-Hartmann wavefront sensor (wavefront measurement + intensity map). Based on this single measurement, a propagation algorithm generates the intensity maps at multiple planes (let’s say N planes) along the optical axis. From these N intensity maps, the M squared value is then computed according to the standard ISO 11146. Note that N is user defined and can be any value above 10. In the Waveview software, one can then access the measurement in any plane of interest without moving and re-aligning the sensor.

CAM SQUARED advantages are :

- Instantaneous M squared measurement. CAM SQUARED requires no translation stages, making measurement cycles very short . The solution is perfectly adapted to pulsed lasers and dynamic applications.

- ISO 11146 standard compliant. The measurement of intensity combined with phase allows to generate 10 to ∞ of frames from which is calculated the M squared factor, such as described in the ISO11146 standard.

- Self aligned. CAM SQUARED requires little alignment, making setup quick and easy.

- No additional optics necessary. The beam under test is directly sent to the CAM SQUARED aperture, no additional optics such as lenses are necessary, which minimizes aberrations that could impair the beam quality. There are also no coatings limiting the range of use of the sensor.

- SM1 thread on the front of the sensor for easy mounting of neutral densities for power adaptation.

- Wavefront sensing option for access to wavefront map, Zernicke polynomials and more.

Applications of CAM SQUARED

CAM SQUARED can be used in many laser-based applications such as:

- Manufacturing, machining

- Imaging, for resolution

- Fiber optics, for coupling

- Free space optical communications and laser radar systems (LIDAR) for better propagation through turbulent atmosphere

Waveview Software Extension for M Squared measurement

CAM SQUARED is delivered with a dedicated extension of WAVEVIEW, the long-proven metrology software from Imagine Optic. This dedicated software is an optimized display of laser quality metrics such as M squared, waist position, beam diameter and more. Using a well known beam propagation algorithm, it provides an instant visualization of intensity maps at any observation plane along the optical axis.

Moreover, this software can be used with an:

- Optional phase measurement extension for wavefront diagnostic and analysis (alignment, collimation, optical aberrations analysis and more than 150 features)

- and/or an Optional SDK in C/C++, LabVIEW and Python

To discover our entire line of M squared measurement systems, click here.

To go to the manufacturer’s website click here.