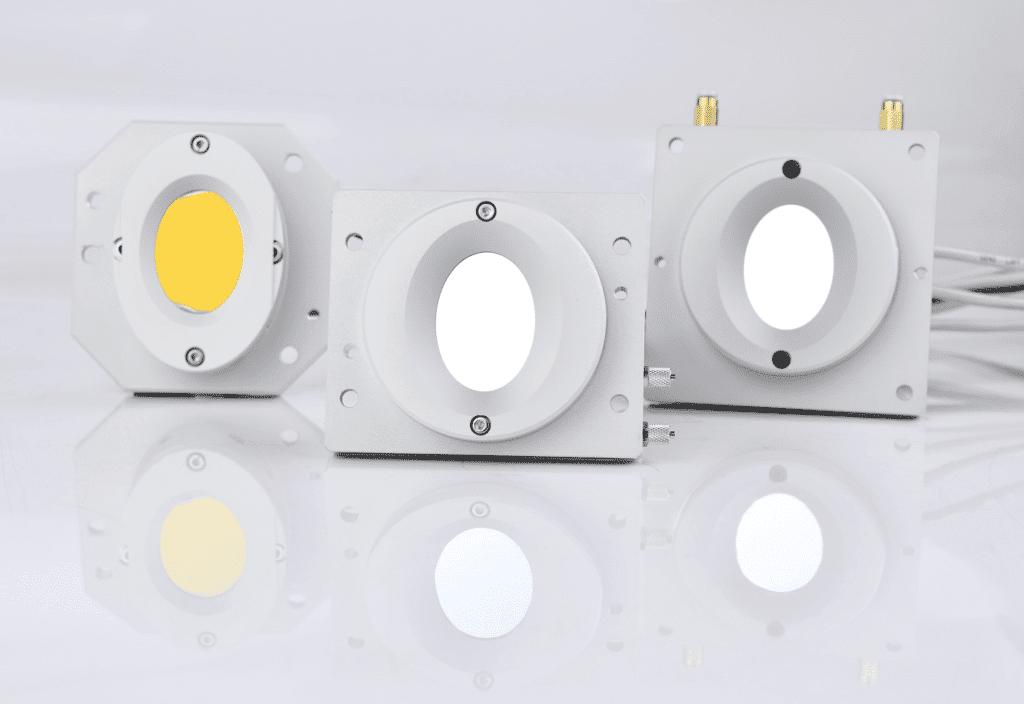

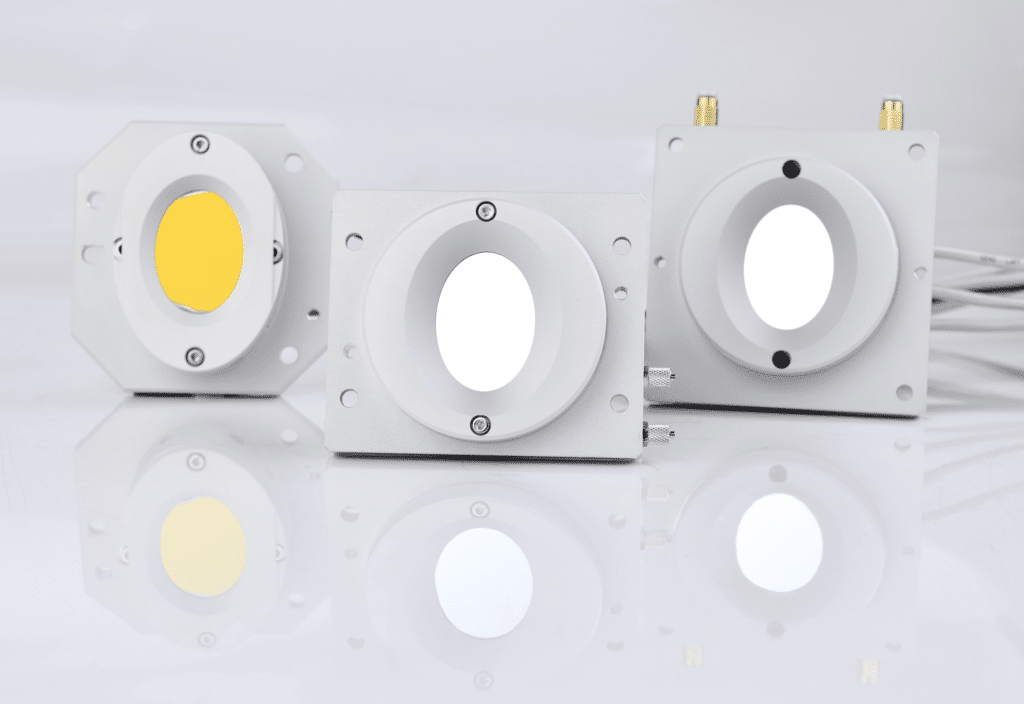

Zwobbel – Fast focusing deformable mirror at 532 nm or 1020 nm

Zwobbel is a fast and power-stable z-axis focusing deformable mirror for laser material processing. The Zwobbel-1020 mirror allows for a significant reduction in processing times for laser welding and cutting – by up to 60%. Indeed, an innovative wobbling process along the z-axis alone replaces the standard wobbling process as the dynamic movement of a spot in a scanning plane . Thus, the spot zwobbles. This additional oscillation in the beam direction offers the possibility of developing entirely new manufacturing processes in laser-cutting, welding, and hardening, and of establishing them in industrial applications. Moreover, the Zwobbel works with single- and multi-mode lasers.

The Zwobbel-532 is designed for structuring applications with a particular focus on high-power beams. This fast focusing deformable mirror can attain a dynamic focus-position shift of 20 mm in 2 ms, and short positioning time results in more dynamic processing. Additionally, the Zwobbel-532 allows for beam refocussing in F-theta applications, with or without F-theta lenses. It may be a substitute for movable lenses.

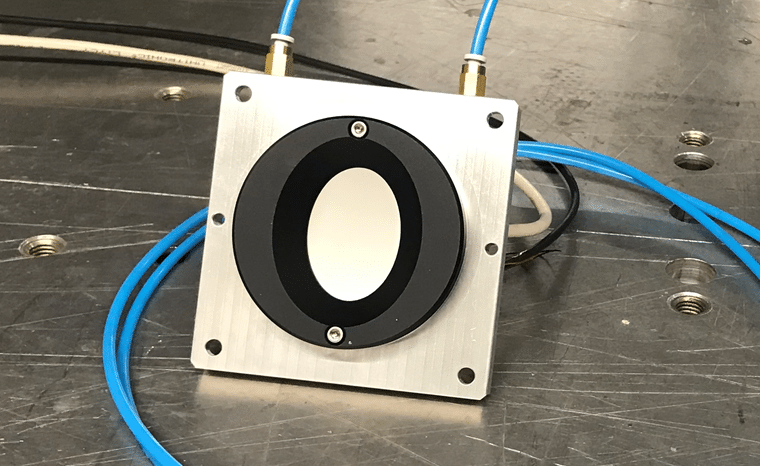

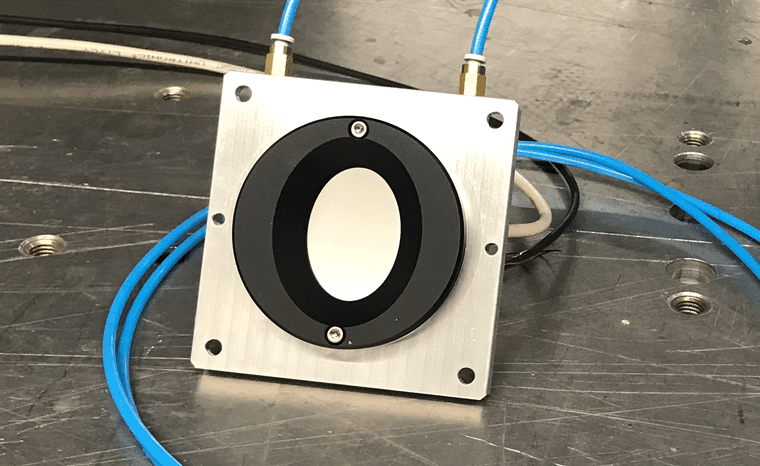

This Zwobbel-532 focusing deformable mirror can be used directly under 90° deflection in the beam guidance system. In combination with its very compact design, this allows the Zwobbel to be integrated into new and existing processing heads of laser material processing machines, independent of wavelength.

How Zwobbel works

Laser machining relies on a laser beam that is focused onto a workpiece. A laser scanner guides the spot is guided along every plane of that workpiece. However, under large deflection angles and/or thick workpieces, the laser’s focus loses its position in the z-direction.

All mirrors based on Zwobbel-technology can hold their focus in the scanning plane as it dynamically changes its shape upon activation. At minimal deflection of the Zwobbel, the focal length of the system is held constant at the nominal focal length of the focusing lens. At the maximum deflection, the focal length of the focusing lens is maximally shifted.

Click here for other adaptive optics solutions.

Manufacturer’s website: here.