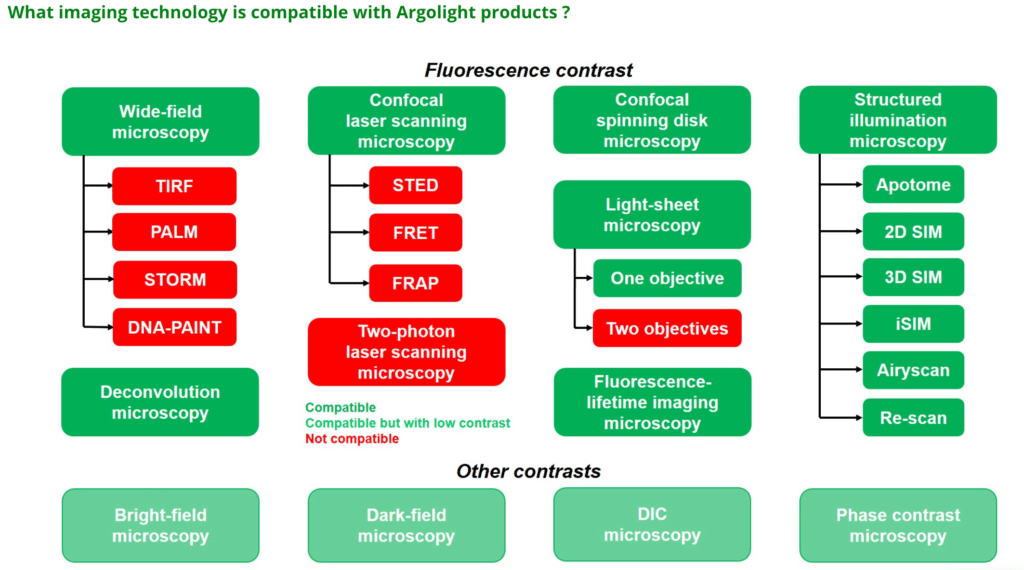

Argolight develops fluorescence microscope calibration slides to ensure your fluorescent based systems provide precise and reliable data. It is designed to help detect microscope troubles and saves you time and effort in detecting the origin of the problem; sample or microscope?

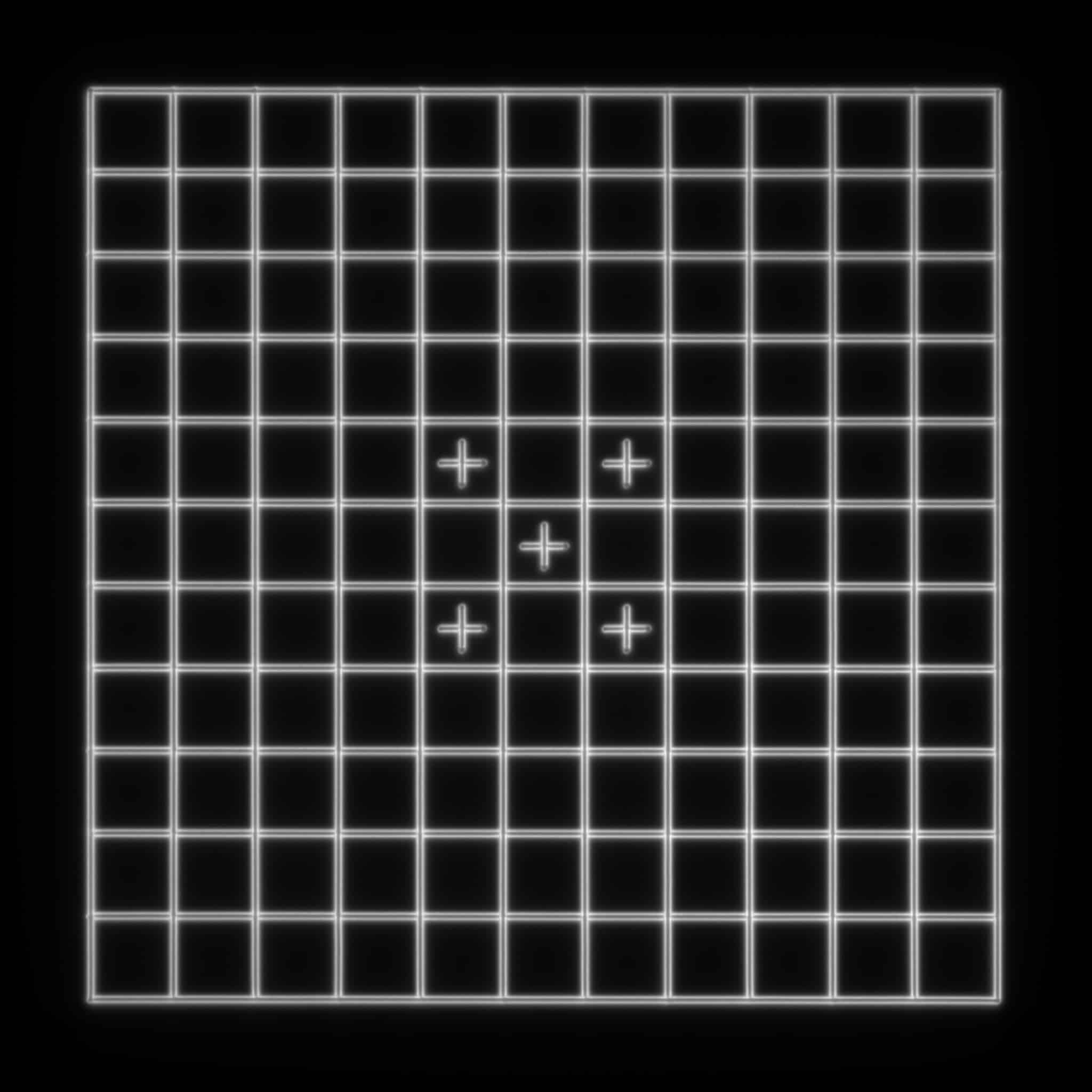

Each Argolight fluorescence microscope slide contains several microscopic fluorescent patterns designed to help the user detect aberration in imaging systems. Their intensity and spectrum are stable in time and under different imaging conditions and the analysis of pattern images can be simplified using Argolight software solutions.

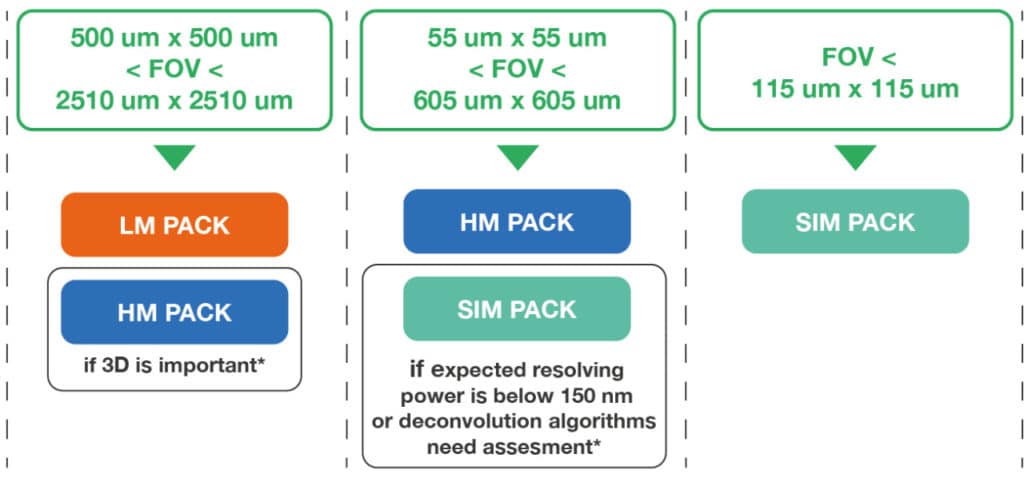

Argolight introduces the new microscope calibration slide with power meter attached, Argo-POWERHM that is specifically designed to assess and follow the performances of fluorescence-based imaging systems, such as wide-field, confocal, spinning disk and other types of microscopes, with high magnification (HM) objectives.

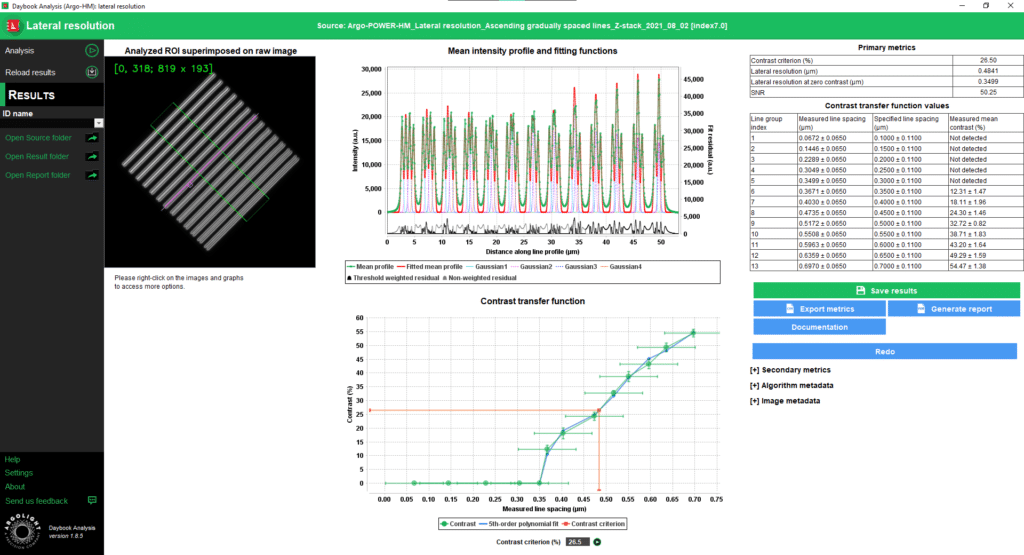

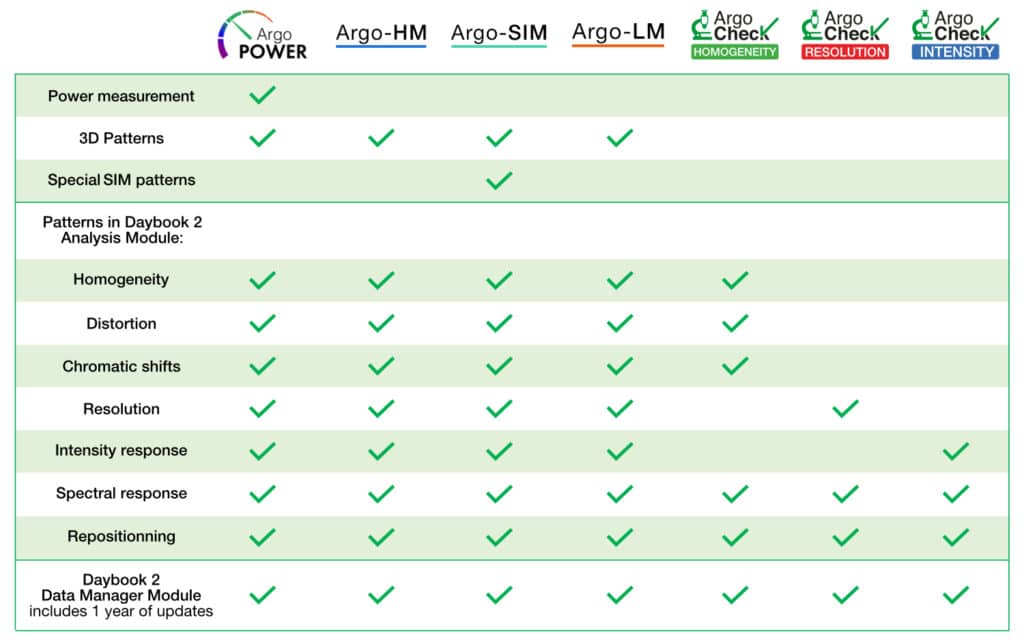

This product is composed of a calibrated optical power meter, an Argo-HM patterned glass. It comes with the Daybook image analysis software. The calibrated optical power meter measures the optical power of light sources of the microscopy setup at the sample plane. The Argo-HM glass is a special glass substrate with different fluorescent patterns embedded inside. Daybook 2 software allows to analyze and extract data from images of the patterns, in order to control significant parameters of your fluorescence imaging system.

Argo-POWERHM microscope calibration slide with power meter is a simple all-in-one device. It plugs into any computer via USB and the software measures the power, assess the quality of the image and manages data. Daybook 2 software can record time-lapse measurements for hours. It allows you to track the quality of the microscope for years as a result of the durability of the slide’s patterns. It also features automatic irradiance estimation live power measurement chart and more.

What is Argolight’s mission?

Argolight microscope calibration slides address a key issue: the difficulty to obtain repeatable results from fluorescent systems. The only way to calibrate and monitor a fluorescence system is to reproduce the features we want to measure and to make those features extremely stable and perfectly known.

This solution allows you to monitor your system’s calibration, quantify the bias, and most importantly correct it.

Argolight uses an exclusive patented technology, to induce fluorescent features into the glass. Those patterns can reproduce cell-like features for the characteristics of size and fluorescence intensity, that are perfectly known and stable. Coupled with our software, we provide a complete fluorescence quality management solution.

How do you induce your fluorescent patterns?

Argolight uses an innovative and patented technology called “fluorescent brush”. This technology induces fluorescent patterns inside transparent materials (from sub-micrometer to centimeter scales) in 3D. This technique combines cutting edge photo-chemistry, optics, and material sciences. The “fluorescent brush” is a non-bleaching technology: all the patterns are stable and re-usable.

How do you manufacture your products?

The core of the microscope fluorescence microscope slide consists of a special glass substrate produced in the Argolight facility to ensure homogeneity and purity. The glass has a tailored formula developed by our scientists from over 10 years of research. Our facility is located in the Argolight headquarters in France. The glass is set on a metallic carrier, featuring the same dimensions as a standard microscope slide (75 mm × 25 mm), except for its thickness that is 1.5 mm. Throughout the whole process, a precision of fewer than 10 microns in all 3 dimensions is maintained to ensure the highest level of assembly. The patterns are then induced by photonics means at Argolight. The patterns and physical properties of the slides are then characterized by cutting edge measuring systems. Each slide is tested and undergoes internal quality control to ensure meaningful test results.

What kind of patterns can we induce?

We can control the size, the shape, and the intensity of the patterns. The elementary structure, i.e. the fluorescent element at the root of any pattern, is an empty cylinder whose dimensions can be adjusted: the length (FWHM) can be varied from 0.5 to 10 µm, the diameter (FWHM) from 0.5 to 2 µm, and the wall thickness (FWHM) from 120 to 550 nm. The section of this cylinder is a ring with the corresponding dimensions.

From this elementary structure, any 3D fluorescent pattern can be painted, from sub-micrometer to centimeter scales. Additionally linear, circular or more complex trajectories at different depths can be painted, with different fluorescent intensity levels.

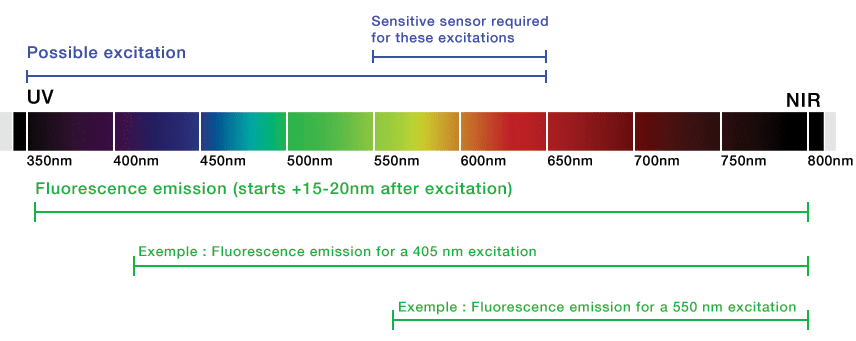

The spectral features of the patterns are remarkable: the excitation and emission ranges are very broad, enabling any chromatic study. The patterns are excitable from 325 to 650 nm (with some limitation depending on the type of slide), and the emission is a continuum ranging from slightly above the excitation wavelength up to 800 nm. The lifetime of the fluorescence is within the nanosecond range.

How stable are the patterns?

Aging and reliability studies have been performed on Argolight fluorescence microscope slides: at 100°C for four months, the emission spectrum of the fluorescent patterns is not modified. We now have more than three years of experience with our products. Our first prototypes was made eight years ago, are still readable and usable today. The fluorescent patterns are guaranteed not to photo-bleach, they can be used for a long period of time (5000 hours), and can be stored without any particular precaution.

What are our certifications?

Today there is no reliable international standard for fluorescence microscopy. We are working hard to establish one with our international partners from National Metrology Institutes and microscope manufacturers. Argolight is currently evaluating several quality control approaches to propose the first NIST traceable tool for fluorescence microscopy.

To learn more about Confocal Microscopy applications, click HERE.