CinSquare M² Measurement Tool

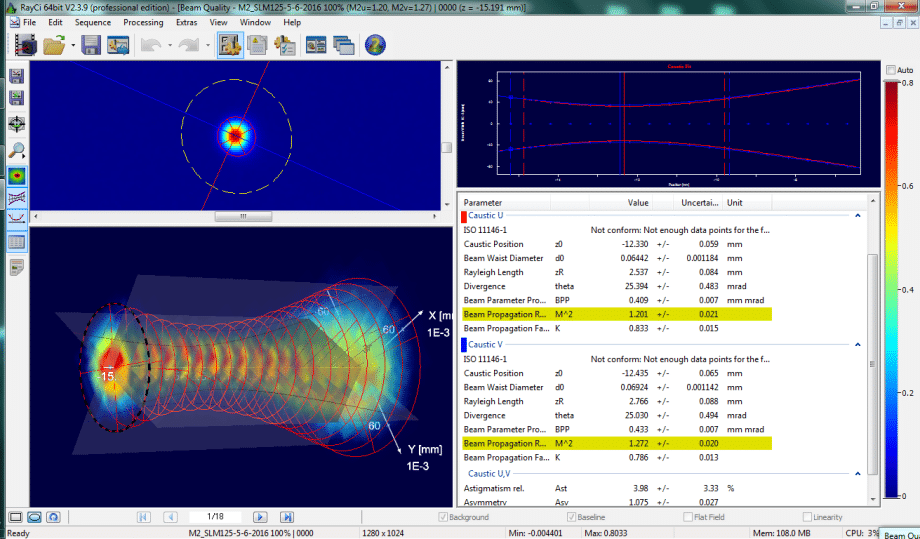

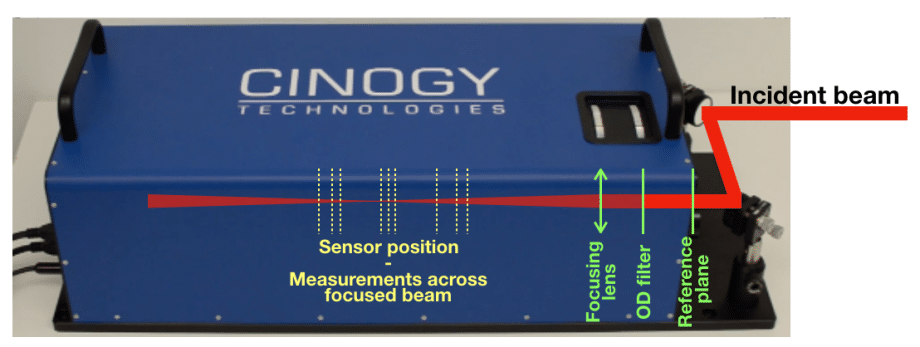

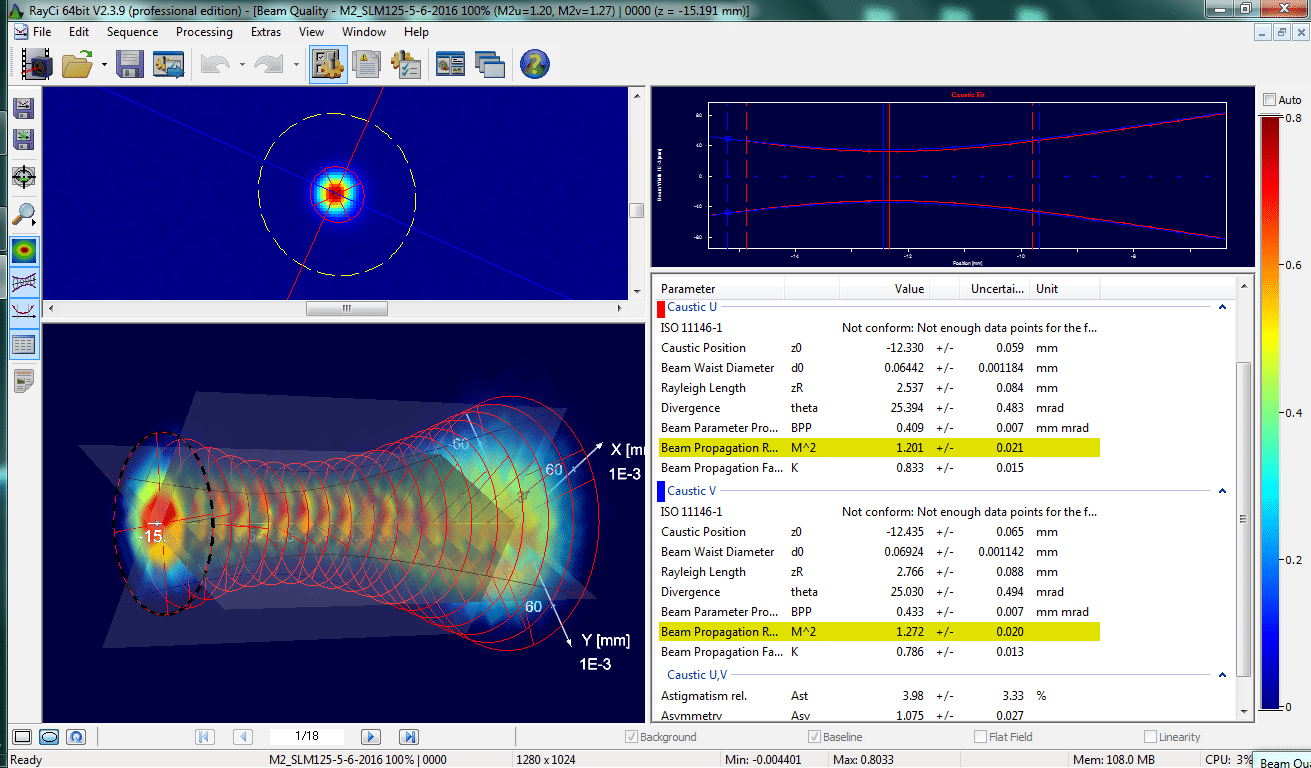

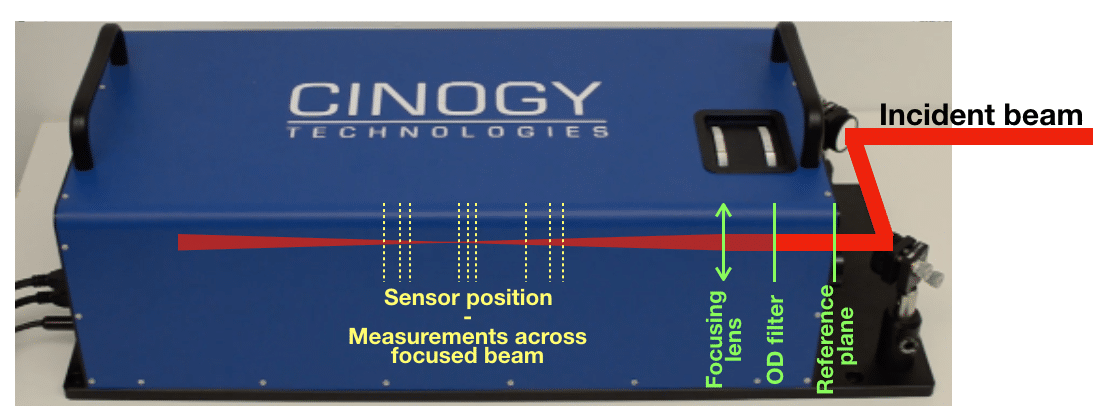

The CinSquare is a fully automated M² measurement system designed for measuring the beam quality across both CW and pulsed laser systems spanning from UV to SWIR wavelengths. Comprising a fixed focusing lens and a motorized translation stage housing the camera-based CinCam CCD/CMOS/InGaAs beam profiler, this system guarantees operational reliability and robustness, making it suitable for continuous use in industrial, scientific, and research environments.

How does the M² measurement system work?

Adhering to ISO 11146-1/2 standards, the CinSquare system measures the complete beam caustic, determining essential parameters such as M², waist position, and divergence relative to the reference plane. For enhanced usability, the system incorporates two alignment mirrors to ensure precise laser beam positioning and a filter wheel for incremental beam attenuation adjustments.

The CinSquare M-squared measurement tool offers customization options tailored to specific wavelengths, beam sizes, and M² values, accommodating diverse application requirements.

CinSquare is customizable for specific wavelengths, beam sizes and M² values.

Learn more about M² measurement and laser beam profiling applications with our application page.