MESO – a multi-wavelength, interference-free optical metrology system with unique capabilities for plane parallel optics

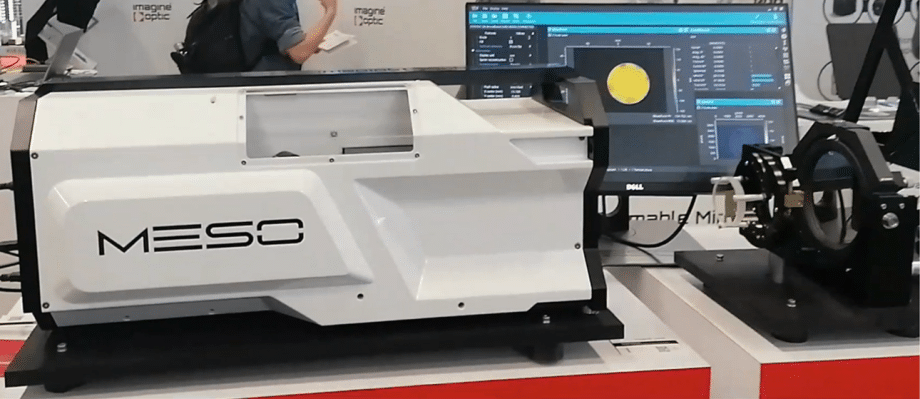

MESO is an easy to use wavefront metrology system specifically designed for the characterization of flat surfaces and plane parallel optics in any environment. MESO outputs a large collimated laser beam (up to 6 inches in diameter) at a user defined wavelength to a sample under test and directly measures the wavefront of the reflected beam using a high resolution HASO LIFT wavefront sensor (680 x 504 resolution).

Because MESO’s principle of operation is not based on interferometry, it presents the following 3 key advantages compared to Fizeau interferometers :

1) Multi-wavelength metrology : Thanks to its interference-free principle of operation, long coherence light sources are not needed and MESO can use multiple cost efficient compact light sources (up to 4 wavelengths in one system) . Choosing your wavelength ( ex : 405nm, 488 nm, 520 nm, 635 nm, 785 nm, 830 nm, 1064 nm) allows users to perform their metrology at the exact wavelength the components were designed for and not make assumptions about their optical components spectral behavior. But one of the most significant advantage of MESO is to offer new and unique ways to characterize coated flat optics such as dichroics. No more struggling with weak reflections from surfaces to inspect, the user can now choose the best wavelength to inspect the same component. A first wavelength can be used to measure the transmitted wavefront error (TWE ) and a second wavelength to measure the reflected wavefront error (RWE ) , all with a simple click !

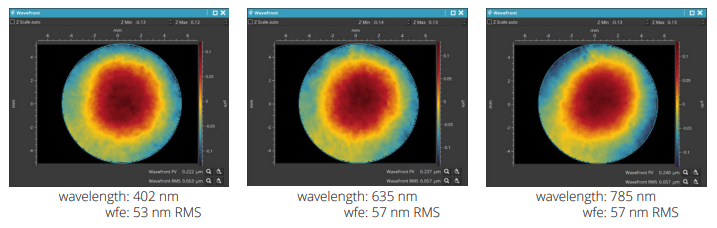

MESO is capable of handling such variety of wavelengths as it was designed to be achromatic from 405 nm to 1064 nm. In the following, several wavefronts were acquired on the same component with 3 different wavelengths (402 nm, 635 nm, 785 nm ) without any system realignment. The data is extremely consistent.

To read our application note entitled “Dichroic mirror testing with MESO” click here.

A white paper about At-Wavelength metrology with MESO was written by the manufacturer Imagine Optic SA, showing this unique capability. Click here to access it.

2) Unmatched and unique plane parallel optics characterization ( patent pending )

Because parallel surfaces generate multiple fringe patterns, interferometry methods struggle to acquire reliable measurements and require the use of more complex techniques using tunable lasers or low coherence sources with scanning. MESO offers the unique capability to separate back and front reflections of plane parallel optics and quantify both separately and accurately with a simple and cost efficient procedure called POP. This Parallel Optics Procedure (POP) requires only two measurements, in transmission and reflection, and is proprietary to Imagine Optic SA and patent pending.

To download MESO white paper about parallel optics testing, click here.

3) Insensitive to vibrations

As it is interference-free and wavefront sensor based, acquiring a wavefront with MESO is as simple and fast as acquiring a single image with a high end Megapixel CMOS camera. The exposure time can be as short as 27 microseconds allowing for measurements in harsh conditions (shop floor).

To download MESO white paper about Shop Floor Measurement, click here.

Key specifications of MESO

- Optical zoom from 1,5’’ (38,1mm) up to 6’’ (152mm) to adapt to your sample size

- Achromatic measurements from 405 to 1064 nm

- Multi wavelength light source with up to 4 lines ( 405nm, 488 nm, 520 nm, 635 nm, 785 nm, 830 nm, 1064 nm)

- 680 x 504 phase points resolution

- Insensitive to vibrations with 27 us minimum acquisition time

- Parallel Optics Procedure (POP)

Useful Links for more information of MESO

For more information on the LIFT technique for high resolution wavefront sensing , read our wavefront sensing application page.

To discover our whole line of optical metrology systems, click here .

To visit the manufacturer’s page, Imagine Optic, click here.

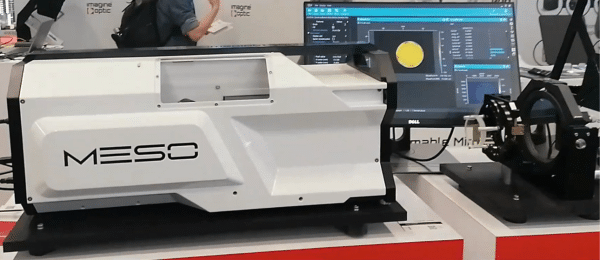

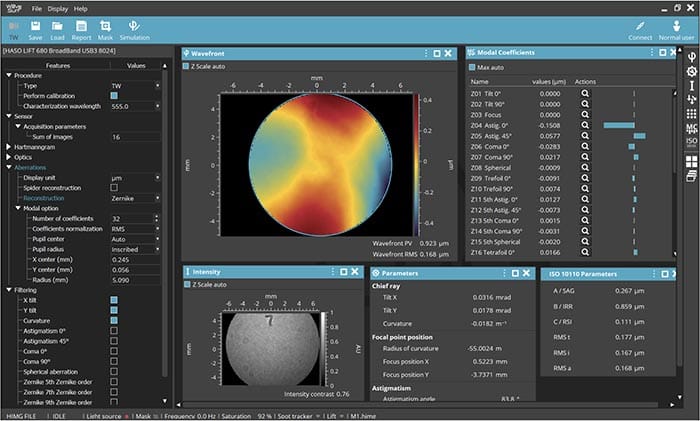

Wavesurf, supportive software for MESO optical metrology system

In just a few clicks, operators and engineers in manufacturing environments can perform wavefront and surface characterization of flat optics and large lenses. With scripted testing procedures to guide users, using Wavesurf makes control easy, automated, and error-proof.

Wavesurf key features are :

- Touchscreen interface control

- Scripted testing procedures guide the user through all the steps

- Automated control of up to 4 embedded wavelengths

- Automated control of test diameter

- Complete automated test report

- ISO10110 standard compliance

- Multiformat data export

MESO is the ideal wavefront metrology system for the control of:

• Parallel Optics

• Screens

• Filters, Dichroics

• Mirrors

• Beamsplitters

• Windows

• Substrates

• Corner cubes

• Crystals

• Rods, Disks

• Glass wafers

• Displays

• Machined surfaces

• Windshields

• Prisms

• Large lenses

• Optical systems

• Beam expanders