Multi-Wavelength Optical Metrology with a Supercontinuum Laser, the HASO RFLEX – SAMBA Combo

In this technical blog we describe how the HASO RFLEX metrology system can be used seamlessly with the SAMBA supercontinuum laser to perform metrology at any wavelength between 400 and 850 nm.

1) HASO RFLEX LA System for Optical Metrology

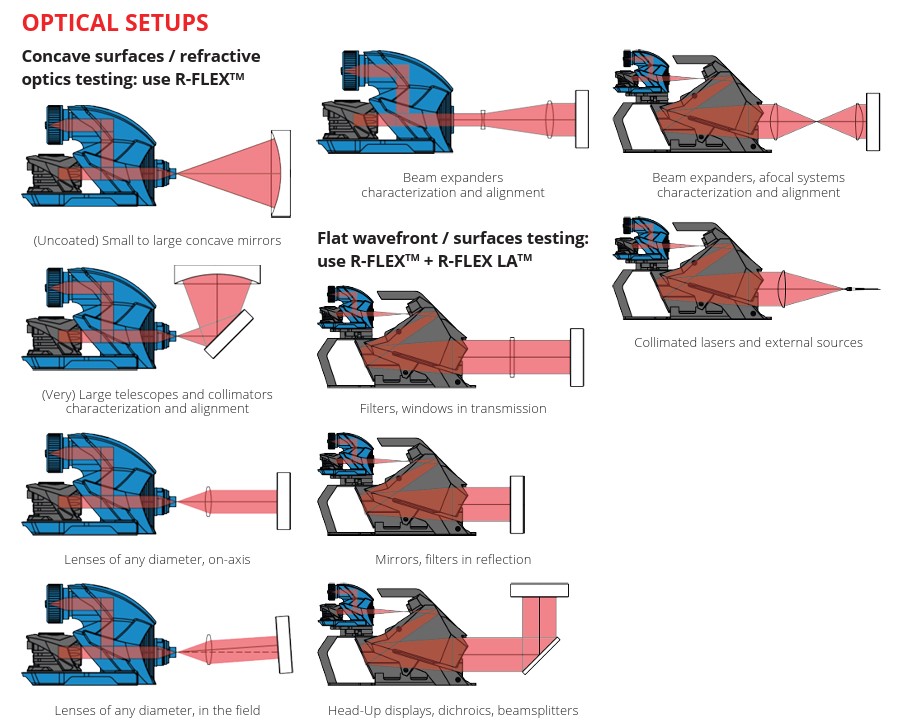

A comprehensive, ready-to-use metrology solution, the HASO RFLEX LA, is designed for characterizing a wide variety of optical components. This modular system comprises a Shack-Hartmann wavefront sensor, a single-mode light source, a focusing module, and a collimator, all controlled by Waveview software for wavefront reconstruction and analysis. The system is suitable for characterizing both flat and non-flat optics, including lenses, mirrors, filters, dichroics, windows, and wafers. The largest available collimator enables the characterization of flat optics up to 150 mm in diameter.

One of the many advantages of the HASO RFLEX LA system is the possibility to use it at different wavelengths. Two versions of the product are offered for VIS-NIR (400 – 1100 nm) and SWIR (900- 1700 nm) spectral bands. A large list of SMLS (single mode and single wavelength light sources) are currently offered as standard accessories, as well as different module to adapt to the numerical aperture of the optics under test.

Figure 2 : The HASO RFLEX LA and the waveview software

In the following, instead of using SMLS sources, we demonstrate that the RFLEX system can also be upgraded with the off the shelf supercontinuum laser SAMBA manufactured by Leukos. Because of its broadband emission, the combination of HASO RFLEX system for optical metrology and the supercontinuum laser SAMBA would be a very convenient system offering wavefront metrology at ANY desired wavelength.

Having the option to choose any wavelength in the 400-850 nm band, is extremely advantageous to measure a variety of dichroic filters for example either in transmission or reflection depending on the choice of wavelength.

Figure 3 : SAMBA compact supercontinuum laser, picture and emission spectrum

System description

The following picture shows the SAMBA laser collimated output connected to the POP VIS module, which is then connected to the FC/APC fiber input of the HASO RFLEX LA via a 10 micron core single mode fiber.

The POP VIS module allows selecting the 400-850 nm part of the supercontinuum laser and fully rejects the rest of the spectrum, especially the very powerful 1 micron seed pump. The desired output wavelength was selected using the POP VIS module equipped with a ½ inch narrowband filter on its output, placed before the fiber coupler. For the present test, we only used four filters, ½ inch diameter, with 10 nm band, centered at 420 nm, 532 nm, 600 nm, and 656 nm. It is of course possible to use as many as desired. We measured that the optical power at the output of the POP module ranged from 1 mW to 5 mW (without any coupler realignment), depending on the wavelength filter used, which is a very comfortable amount of power to work with the HASO RFLEX LA system.

Figure 4 : The HASO RFLEX LA connected to the SAMBA supercontinuum laser and POP VIS module

Instead of a POP module where filters are placed manually, it is also possible to use a motorized tunable filter such as the BEBOP which uses a moving linear filter or even the TANGO filter which uses an acoustic optic tunable filter.

Mirror surface measurements with RFLEX LA75 + SAMBA Supercontinuum Laser

The flat mirror under test is a 2 inches (50 mm) diameter silver coated mirror with a surface quality of 𝞴/10 rms as specified by the manufacturer. At each wavelength, a reference measurement was originally performed on a reference mirror (Lambda/20 PtoV) to remove the optical aberrations inherent to the HASO RFLEX metrology system. This reference measurement is then subtracted from any measurements carried out on the flat mirror under test. Below images show the 75 mm beam output by the entire HASO RFLEX 75 system, with different filters used in POP VIS module.

Figure 5 : observing the 75 mm output beam when changing the wavelength of operation

Before acquiring the wavefront, the mirror under test is carefully aligned in a few seconds using the live alignment parameters offered by the Waveview software. X and Y tilts are being nulled.

4) Results

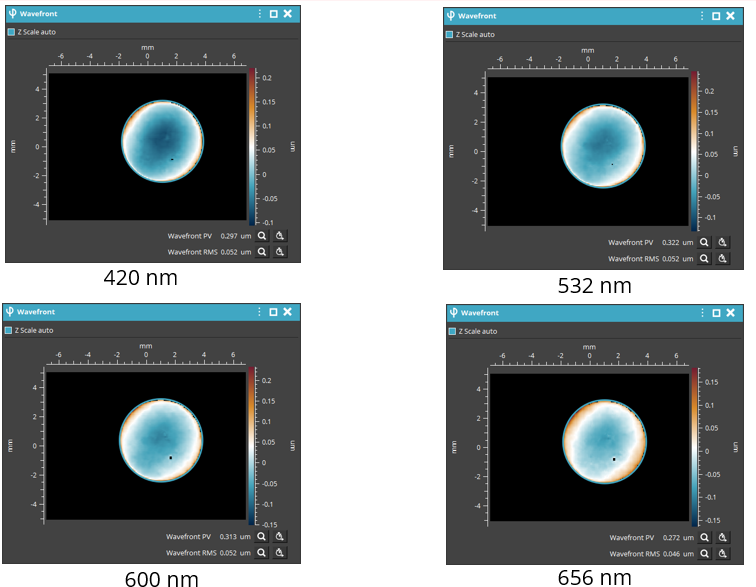

With the Waveview software, at each wavelength, we acquired and analyzed the wavefront maps of the mirror surface. As we can observe in fig. 6 below, the surfaces look strikingly similar.

Figure 6 : Surface measurements of the same mirror performed at 4 different wavelengths

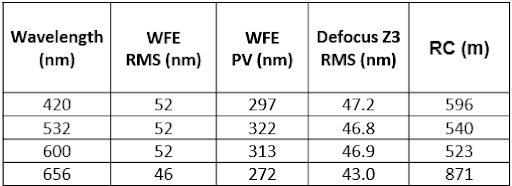

For further analysis, in table 1 below, we plotted the data of the wavefront error (in nm); the exposure time of each measurement (in µs), the measured defocus (in nm RMS). The last column shows the real radius of curvature of the sample, taking into account the magnification of the system.

Our measurements show that the mirror is mostly curved with a defocus value almost as large as the total wavefront error. The extremely small variation of the WFE rms along with the wavefront images collected demonstrates that the system performs very well for the 4 wavelengths and exhibits a fully achromatic behavior. Although measurements below 420 and above 656 nm are not shown in this measurement set, we measured that this behavior is consistent across the whole spectral band from 400 to 850 nm.

Optical power compatibility

The exposure times available on the HASO RFLEX system range from 26 µs to several seconds. As we used between 50 and 700 µs for this experiment, we can confirm that the amount of optical power was well adapted. The present test was on a highly reflective component, but we can conclude that the SAMBA laser + HASO RFLEX combination would also work nicely on low reflective surfaces with only a few % reflection (uncoated glass for example) . For each wavelength, the output power of the SAMBA varies (it is typically more powerful in green than in blue). Since it operates as a 1 ns pulse laser at 30 kHz, exposure time plays a critical role. For example, in our case, when the exposure time was set to 50 µs (for both red wavelengths), a single pulse was captured.

To perform power adjustments, the following controls are available :

- exposure time on wavefront sensor (up to several seconds possible)

- repetition rate of the SAMBA laser (between 1 and 30 Khz)

- bandwidth of the selection filter (5 to 20 nm)

- use an additional slot on the POP VIS module to place ND filters to attenuate the beam.

Easy alignment

To take reference and sample measurements, we align the high quality reference mirror or the mirror under test in front of the HASO RFLEX system by rotating it and zeroing the X and Y tilt values provided by the waveview software in real time. A satisfying tilt value below 0.5 mrad is very easy to obtain in a few seconds. Changing the wavelength by swapping the filter at the output of the POP laser, takes only a few seconds and does not require any alignment, therefore ensuring quick acquisition of all wavefronts at multiple wavelengths in a few minutes. In our case, we could do 4 wavelengths in approximately 15 minutes.

5) Conclusions:

Thanks to this brief experimental work, we have demonstrated that optical metrology with a supercontinuum laser is very easy to implement and use. The SAMBA supercontinuum laser is perfectly suited to the HASO RFLEX LA metrology system. In this document, the following points were addressed:

- SAMBA + POP VIS module easily connects to the RFLEX LA with a single mode fiber

- Wavefront Measurements performed were identical across the whole 420- 656 nm band showing excellent measurement accuracy across that band. The same accuracy is expected across the 400- 850 nm band offered by the SAMBA supercontinuum laser. The HASO RFLEX is specified for an even larger band of 400 -1100 nm.

- The optical power and power controls available allow us to comfortably characterize highly reflective or low reflection surfaces without the need for extra attenuation systems.

- Switching wavelength and aligning the unit for taking reference or sample measurements is very simple and easy, making the system easy and quick to use, with a single measurement being performed in a few minutes.

To find more optical metrology and wavefront sensing posts, click here.