SWIR Cameras & Cores

Shortwave infrared (SWIR) cameras detect photons with wavelengths ranging from 900 nanometers (nm) to 2500 nm, a spectral band that lies beyond the visible spectrum (400–700 nm) and the near-infrared (NIR) range (700–900 nm). This region of the electromagnetic spectrum is particularly valuable because SWIR light interacts with objects in a manner similar to visible light—it is reflective rather than emissive, meaning it bounces off surfaces rather than being emitted as thermal energy, as occurs in the mid-wave (MWIR) or long-wave infrared (LWIR) bands. As a result, SWIR cameras produce images with shadows, contrast, and fine detail that closely resemble visible-light photographs. This reflective property arises from the fact that SWIR wavelengths are short enough to scatter off small surface features but long enough to penetrate certain materials and atmospheric obscurants like fog, haze, or smoke, which scatter shorter visible wavelengths more aggressively due to Rayleigh scattering principles. For more information on the differences between SWIR, MWIR and LWIR, visit our blog post ‘The Differences between SWIR, MWIR and LWIR cameras’.

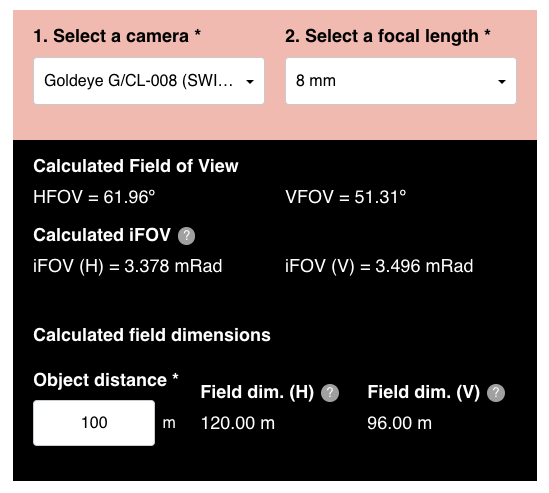

The resolution and detail achievable with a SWIR camera stem from the physics of photon detection and the optical systems employed. Unlike thermal imaging, which relies on detecting emitted heat and typically produces lower-resolution images due to longer wavelengths (3–5 μm for MWIR and 8–14 μm for LWIR), SWIR cameras benefit from shorter wavelengths that allow for tighter diffraction-limited resolution. For instance, the Rayleigh criterion for resolution scales inversely with wavelength, so a 1.5 μm SWIR system can theoretically resolve details roughly 2–3 times finer than a 5 μm MWIR system with the same aperture size. This makes SWIR cameras ideal for applications requiring high spatial fidelity, such as industrial inspection, surveillance, and scientific imaging.

Because standard silicon-based sensors, such as those found in conventional CMOS or CCD cameras, have a sensitivity cutoff around 1000 nm due to silicon’s bandgap energy of approximately 1.1 electron volts (eV), they are inadequate for capturing the full SWIR spectrum. Silicon’s quantum efficiency drops sharply beyond 900 nm as photons lack sufficient energy to excite electrons across the bandgap, rendering it ineffective for wavelengths above 1000 nm. To overcome this limitation, SWIR cameras employ specialized sensors made from compound semiconductors like indium gallium arsenide (InGaAs). InGaAs sensors are tailored for the 900 nm to 1700 nm range and offer high quantum efficiency—typically exceeding 70%—meaning they convert a large fraction of incoming photons into detectable electrical signals. The bandgap of InGaAs (approximately 0.73 eV for standard compositions) aligns well with SWIR wavelengths, enabling efficient photon absorption and detection. Learn more about InGaAs’ origin and manufacturing techniques for SWIR Imaging, visit our blog post ‘What is InGaAs?’.

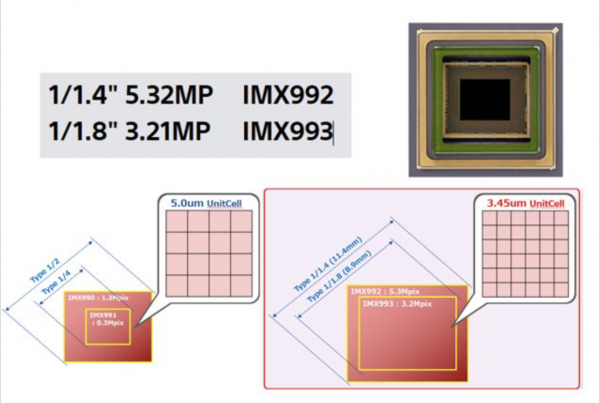

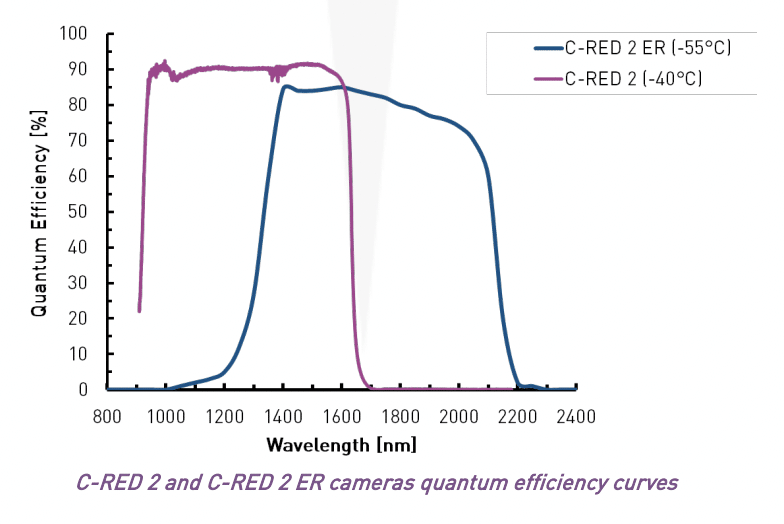

Recent advancements in InGaAs technology have expanded its capabilities further. For example, Sony’s SenSWIR™ technology integrates InGaAs with advanced pixel architectures to extend sensitivity into the visible range, covering 400 nm to 1700 nm in a single sensor. This is achieved through thinner InGaAs layers and optimized anti-reflective coatings, allowing shorter-wavelength photons to penetrate and be detected effectively. For more information on the SenSWIR technology, visit our blog post about the ‘IMX992 sensor’. To le Additionally, extended-range InGaAs sensors push the upper limit beyond the traditional 1700 nm cutoff to 2200 nm by adjusting the indium-to-gallium ratio in the alloy, which lowers the bandgap further (e.g., to ~0.5 eV). These extended-range sensors are critical for applications like hyperspectral imaging, where distinguishing molecular absorption features—such as water or hydrocarbon bands around 1900–2000 nm—is essential. However, these advancements come with trade-offs, including increased dark current (noise from thermally generated electrons) at longer wavelengths, necessitating cooling systems like thermoelectric coolers (TECs) to maintain signal-to-noise ratios, especially in low-light conditions.

Extended range SWIR imaging

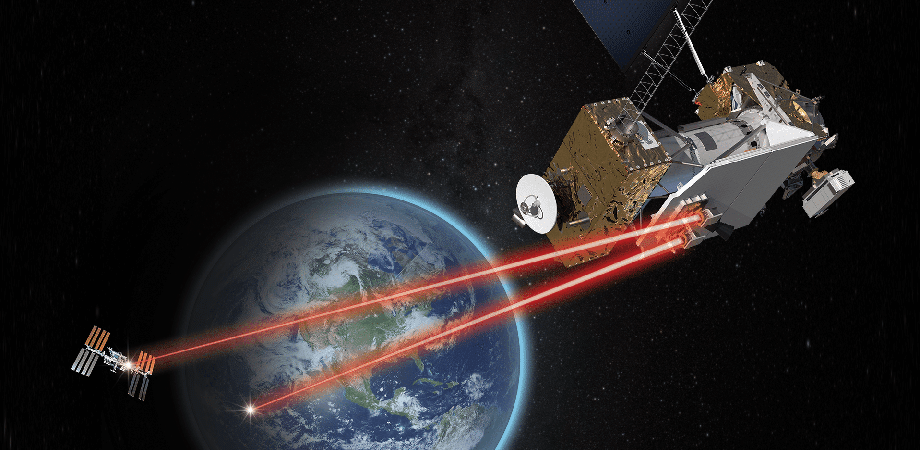

Extended range SWIR imaging FSO & AO

FSO & AO Long exposure times up to 2 min

Long exposure times up to 2 min