Industrial High Power Laser Beam Profiler

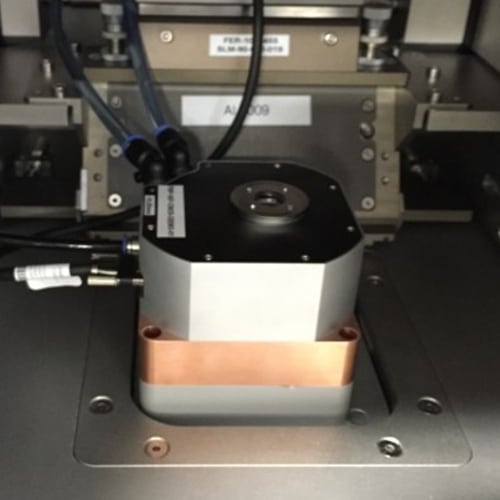

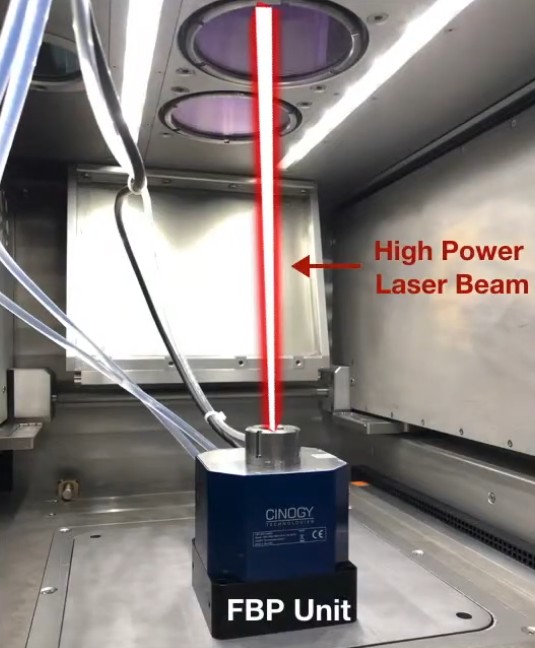

The Focus-Beam-Profiler, FBP, is powerful and a compact tool tailored for measuring focused laser beams, typically found in high-power lasers used in 3D printing machinery like SLM, EOS, and 3D Systems. Its operational durability and dependability ensure continuous use applications in demanding environments, particularly in industrial settings. The entire measuring process is controlled by CINOGY ́s RayCi Software.

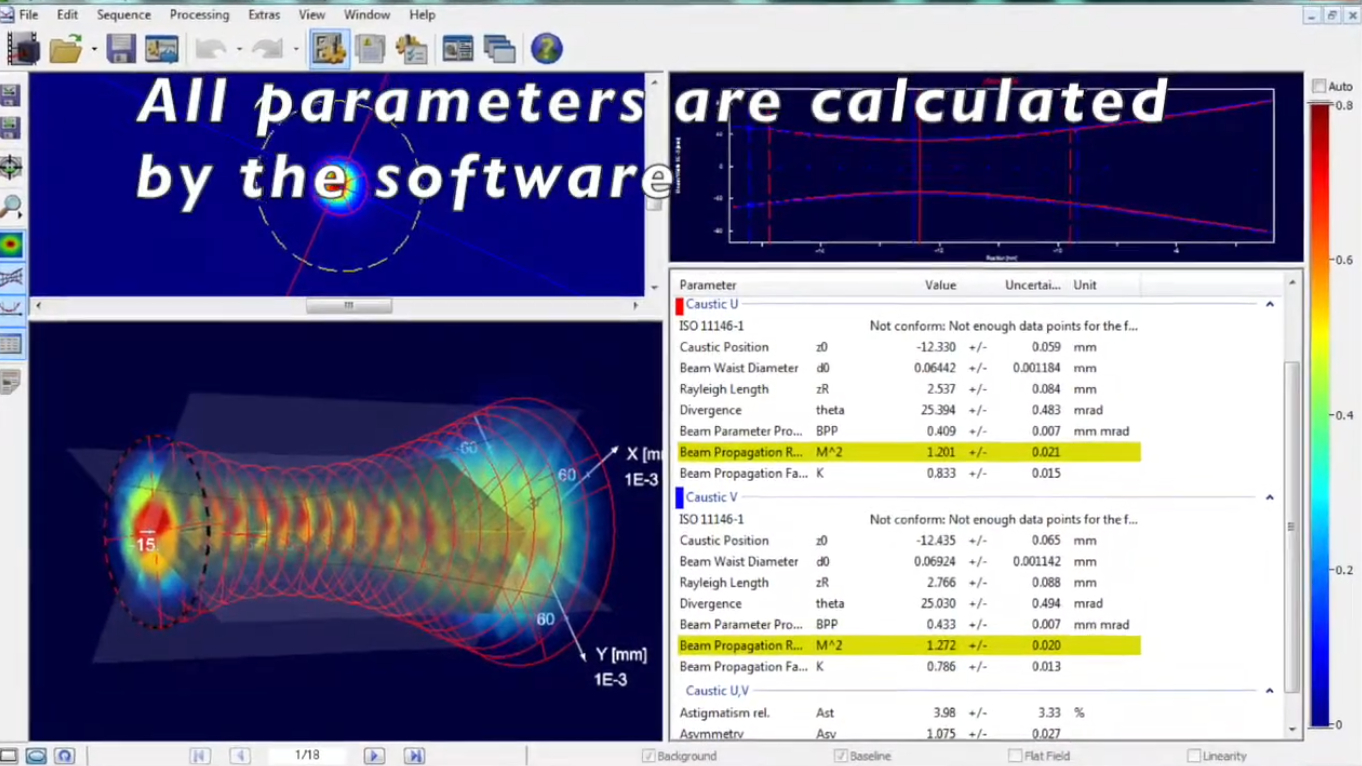

The FBP works by maintaining a fixed measurement position, featuring a compact design. Its optical design allows broadband usage ranging from 340nm to 1150nm, covering the primary wavelengths used in material processing. The accompanying software provides comprehensive caustic information, including M2 value, waist size, and absolute waist position, among other parameters. Each FBP unit undergoes calibration to guarantee precise delivery of the absolute waist position (z0) with an accuracy of 50µm.

- Up to 2 kW @ 1030nm-1070nm

- Compact design, easy operation and highest accuracy

- High-resolution CMOS sensor and short measurement time

- Focused beam parameters: Waist diameter, Absolute caustic position, Rayleigh Length, M2 values.

- ISO standard measurements: 11146-1 (stigmatic and simple astigmatic beams) and 11146-2 (general atigmatic beams)

NEW: FBP for 2kW lasers

The FBP-3KF is not a radical departure but a powerful evolution, following the established, successful design principles of its predecessors, the widely-used 400 W and 1 kW versions. This consistency ensures familiarity for existing users while delivering enhanced performance. At its core, the FBP-3KF is an advanced multi-stage high-performance attenuator system. This specialized attenuation mechanism is crucial: it safely and accurately reduces the intense power of the 2,000 W focused beam down to a level that can be precisely measured by a high-resolution CMOS sensor. By meticulously managing the thermal load and optical path, the FBP-3KF guarantees that the critical beam parameters—such as beam waist, quality factor, and focus spot size—are preserved and accurately represented without distortion, even under maximum load.

Its compact footprint allows for easy placement and setup, often simplifying the process quick quality checks directly on the production floor. The ability to handle up to 2,000 W makes it an essential tool for manufacturers and research facilities utilizing the latest generation of powerful lasers, providing the necessary quality assurance and process optimization data to maintain high efficiency and precision in their applications.

For more information on laser additive manufacturing, visit our application page.

Focus Beam Profiler Applications

- Laser Additive Manufacturing