CinSquare M² Measurement Tool

The CinSquare is a fully automated M² measurement system designed for measuring the beam quality across both CW and pulsed laser systems spanning from UV to SWIR wavelengths. Laser technology is a cornerstone of modern manufacturing, offering numerous benefits in p rocesses like welding, cutting, marking, and metrology by accelerating and simplifying tasks. The increasing demand for high-quality products also drives the widespread adoption of lasers. However, laser-based processes are highly susceptible to various internal and external factors, including resonator misalignment, incorrect pressure, or even dirty mirrors and lenses. These issues can lead to undesirable changes in beam position and quality. To prevent inefficient and unstable processes, which can result in slower production and higher costs, continuous monitoring of beam parameters is crucial.

rocesses like welding, cutting, marking, and metrology by accelerating and simplifying tasks. The increasing demand for high-quality products also drives the widespread adoption of lasers. However, laser-based processes are highly susceptible to various internal and external factors, including resonator misalignment, incorrect pressure, or even dirty mirrors and lenses. These issues can lead to undesirable changes in beam position and quality. To prevent inefficient and unstable processes, which can result in slower production and higher costs, continuous monitoring of beam parameters is crucial.

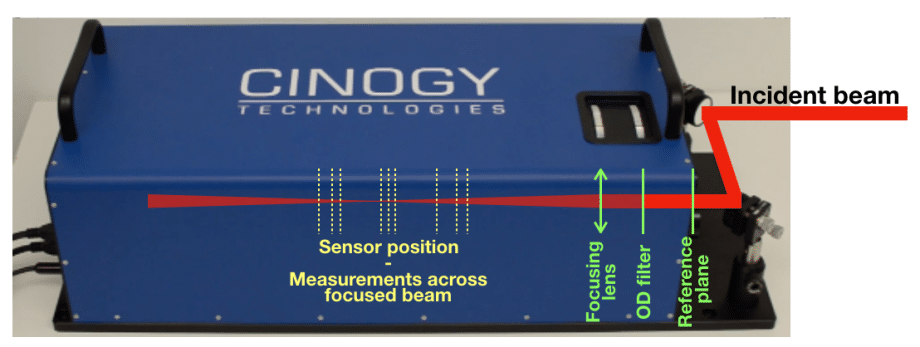

The CinSquare system provides a compact and fully automated solution for measuring the M² beam quality of both continuous wave (cw) and pulsed laser systems. Its components are pre-assembled on a mounting board for straightforward operation and can be customized to suit specific customer laser parameters.

A Robust and Versatile M² Measurement System

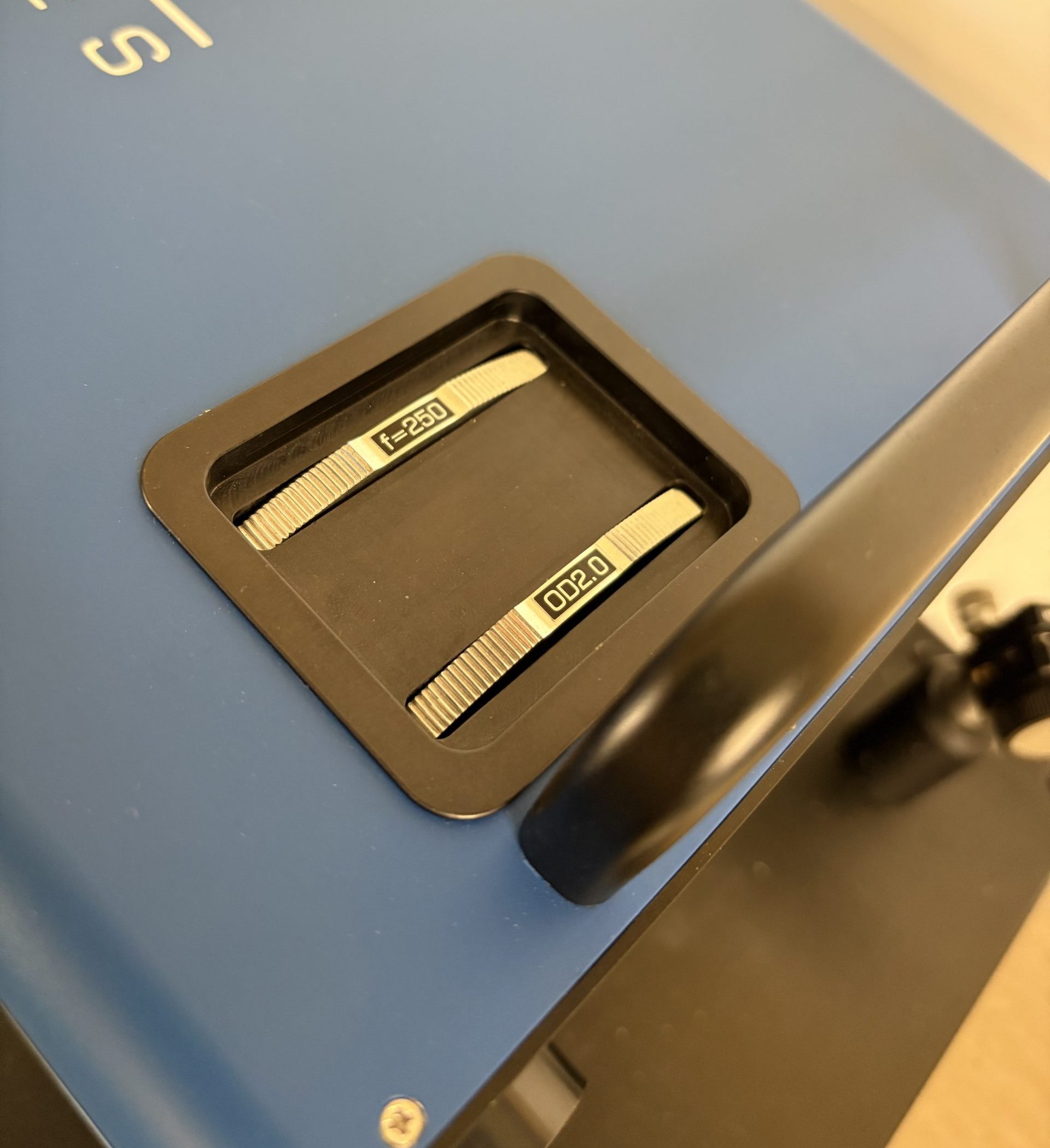

The CinSquare M² measurement system stands out for its adaptability. Central to its design are two alignment mirrors, which guarantee the  exact and reproducible positioning of the laser beam as it traverses the entire measurement setup. Furthermore, the CinSquare system incorporates features for beam conditioning. It is equipped with an array of up to 6 interchangeable ND filters in a filter wheel , allowing for incremental attenuation of the laser beam’s intensity, ensuring that measurements can be performed across a wide range of laser powers without saturation or damage. Complementing the filters are focusing lens wheels, which provide the flexibility to adapt the system to diverse beam conditions, including varying beam diameters and divergences. This modular approach ensures that the CinSquare system can be seamlessly integrated into various setups, accommodating different laser types and applications. Its operational robustness and reliability ensure continuous use in all applications in industry, science, research and development.

exact and reproducible positioning of the laser beam as it traverses the entire measurement setup. Furthermore, the CinSquare system incorporates features for beam conditioning. It is equipped with an array of up to 6 interchangeable ND filters in a filter wheel , allowing for incremental attenuation of the laser beam’s intensity, ensuring that measurements can be performed across a wide range of laser powers without saturation or damage. Complementing the filters are focusing lens wheels, which provide the flexibility to adapt the system to diverse beam conditions, including varying beam diameters and divergences. This modular approach ensures that the CinSquare system can be seamlessly integrated into various setups, accommodating different laser types and applications. Its operational robustness and reliability ensure continuous use in all applications in industry, science, research and development.

ISO 11146 Compliant M² Measurements

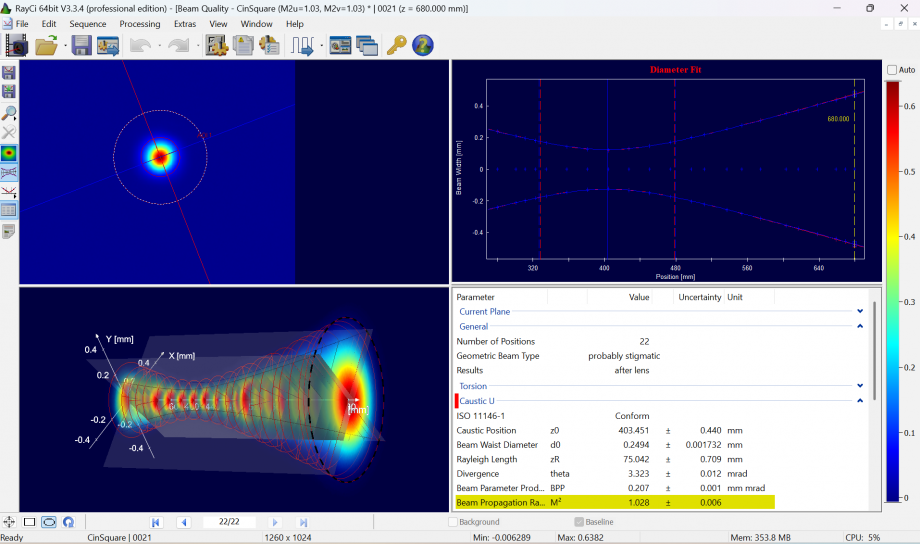

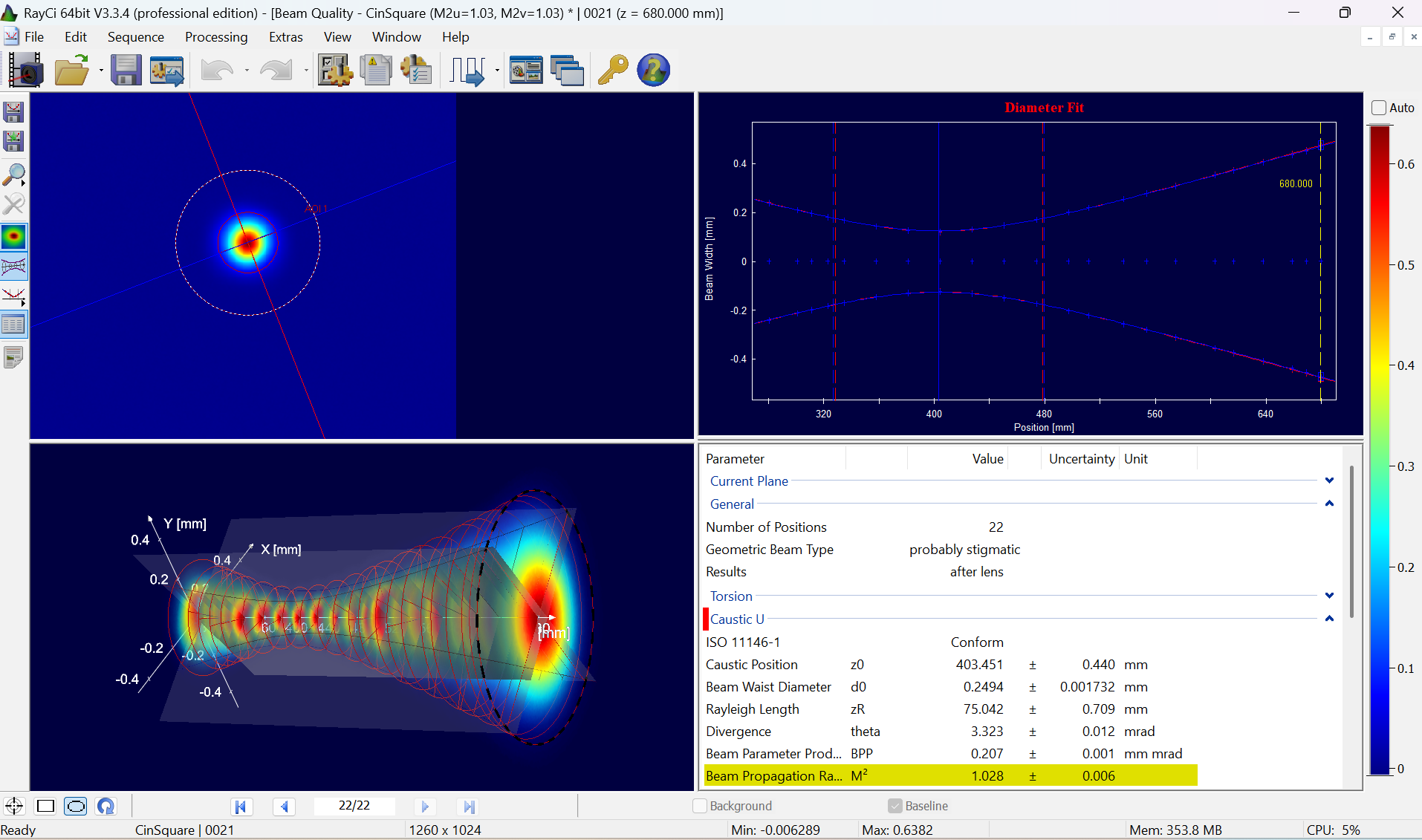

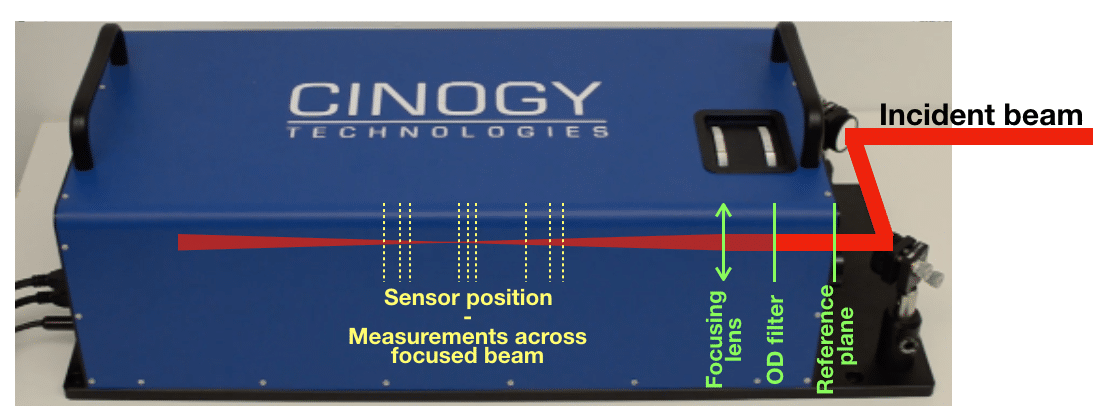

The CinSquare M² measurement system performs beam quality measurements according to ISO 11146 and is fully automated. The system measures the complete beam caustic and determines M², waist position, divergence, etc., related to the reference plane. This is accomplished by multiple beam diameter measurements of a beam focused with an aberration-free lens using a motorized translational stage carrying a camera based beam profiler.

Providing a fast scan option, it is possible to obtain complete beam quality measurements in about 30-60 seconds.

How does the M² measurement system work?

Adhering to ISO 11146-1/2 standards, the CinSquare system measures the complete beam caustic, determining essential parameters such as M², waist position, and divergence relative to the reference plane. For enhanced usability, the system incorporates two alignment mirrors to ensure precise laser beam positioning and a filter wheel for incremental beam attenuation adjustments.

The CinSquare M-squared measurement tool offers customization options tailored to specific wavelengths, beam sizes, and M² values, accommodating diverse application requirements.

CinSquare is customizable for specific wavelengths, beam sizes and M² values.

Learn more about M² measurement and laser beam profiling applications with our application page.