EoSens high-speed machine vision CMOS cameras, in a nutshell

The EoSens® cameras series, manufactured by Mikrotron, are high-speed streaming CMOS cameras dedicated to machine vision applications. They come in three different digital interfaces (Camera Link, CoaXPress 1.0 or CoaXPress 2.0), two different sensor chroma (monochrome or color) and a variety of lens interfaces (C-mount, F-mount, T-mount, TFL-II-mount or Flat Front). All models are global shutter cameras, which usually is a very strong requirement for high-speed machine vision applications.

The EoSens® high-speed CMOS cameras are utilized in industrial image processing wherever it is necessary to analyze processes occurring within just a few milliseconds. With frame rates reaching up to 225,000 fps (for small region of interest), they enable extremely precise examination of processes and objects. If high resolution is a priority, recording speeds of several hundred frames per second remain achievable.

EoSens high-speed machine vision CMOS cameras, in more details

Sensor Chroma: Monochrome & Color

All EoSens® models come in a monochrome version, and the CoaXPress 2.0 models also come in a color version in standard (EoSens1.1, EoSens2.0, EoSens9.5, EoSens10 & EoSens21). The Camera Link and CoaXPress 1.0 models (EoSens1.3, EoSens3.0 & EoSens4.0) can come in color version, but those are manufactured on request.

Digital Interface: Camera Link, CoaXPress 1.0 & CoaXPress 2.0

The EoSens® cameras series comes in three interface variations: Camera Link, CoaXPress 1.0 (CoaXPress-6) or CoaXPress 2.0 (CoaXPress-12). Camera Link maximum transfer speed is 6.8 Gb/s for a single line, or 13.6 Gb/s for two lines. CoaXPress 1.0 maximum transfer speed is 6.25 Gb/s for a single line, or 25 Gb/s for 4 lines. CoaXPress 2.0 maximum transfer speed is 12.5 Gb/s for a single line, or 50 Gb/s for 4 lines.

Camera Link:

The EoSens® Camera Link series delivers the highest image quality at high frame rates. The extremely robust Camera Link interface transfers 850 MB per second in full deca mode and allows unique programming direct access to the image sensor. The series offers advanced image processing features such as multiple ROIs in any shape, FPN correction and the generation of high contrast images with the Extended Dynamic Range function. If you are looking for a Camera Link camera, check the EoSens1.3 and EoSens3.0.

CoaXPress 1.0:

CoaXPress was developed to meet the increasing bandwidths of new sensor generations. Up to 6.25 GBit/s are transmitted per line. The EoSens® high-speed cameras with CoaXPress-6 support up to 4 CoaXPress lanes in parallel. This makes the CoaXPress interface very suitable for transporting the large data volumes of a high-speed camera with high resolution. If you are looking for a Camera Link camera, check the EoSens3.0 and EoSens4.0.

CoaXPress 2.0:

CoaXPress-12 is ideal for applications with highest data rates. Using four parallel lanes, data rates of up to 50 Gbit/s are possible. State-of-the-art high-speed image sensors with high resolution and frame rate are thus read out at maximum speed in the EoSens® series. With the standardized CoaXPress-12 interface, the high-resolution Mikrotron EoSens® cameras deliver the highest frame rates with minimal jitter. If you are looking for a Camera Link camera, check the EoSens1.1, EoSens2.0, EoSens9.5, EoSens10 and EoSens21.

Lens Interface: C-mount, F-mount, M42x0.75, M58x0.75 & Flat Front

Each EoSens® models come with two mount variations:

- C-mount or F-mount for the EoSens1.1, EoSens1.3, EoSens2.0, EoSens3.0 & EoSens4.0 ;

- Flat Front or M42x0.75 for the EoSens10 ;

- Flat Front, F-mount or M58x0.75 for the EoSens9.5 & EoSens21.

C-mount:

The C-mount standard is one of the most common lens mount types in machine vision. The C-Mount standard features a thread 1” in diameter with 32 threads per inch (TPI). The C-mount flange distance is 17.526 mm. The C-mount lens interface can be used with sensor diagonal of up to 18 mm. It is ideal for many industrial applications, as the threaded mount provides a robust, controlled interface between the camera and lens.

F-mount:

The F-mount standard is a bayonet-style mount common with line scan cameras and large format cameras. The F-mount standard features a diameter of 44 mm and a flange distance of 46.5 mm. The spring-loaded bayonet connection provides ease of use for photographers but can contribute to camera-lens misalignment in industrial applications.

M42x0.75:

The M42x0.75 or T-mount is a lens mount used with camera sensors between the C-mount and F-mount. The M42x0.75 stnadard features a diameter of 42 mm and a flange distance of 17.526 mm.

M58x0.75:

The M58x0.75 or TFL-II-mount was designed for APS-H (35mm) sensors and consists of the same 17.526 mm flange distance but with M48x0.75 thread dimensions, it can be used with sensor diagonal up to 35 mm so also a good option for camera sensors too large for C-mount.

Flat Front:

Larger EoSens® models can come with the flat front interface, which is basically no lens interface and a 75 mm diameter recessed interface to connect the adapter of your choice.

EoSens1.1

eGrabber Acquisition Software for High Speed Machine Vision Camera

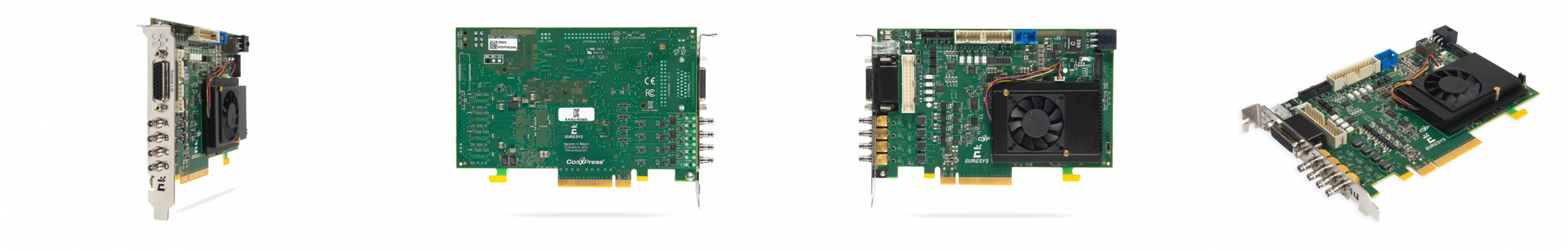

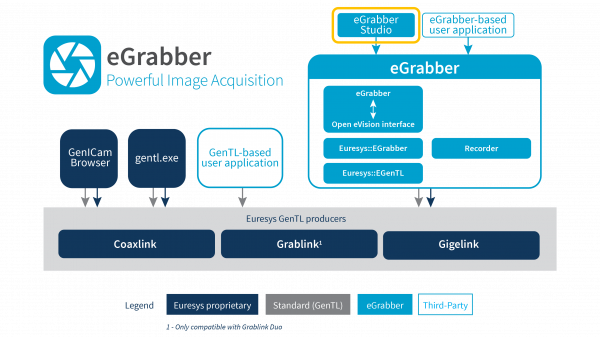

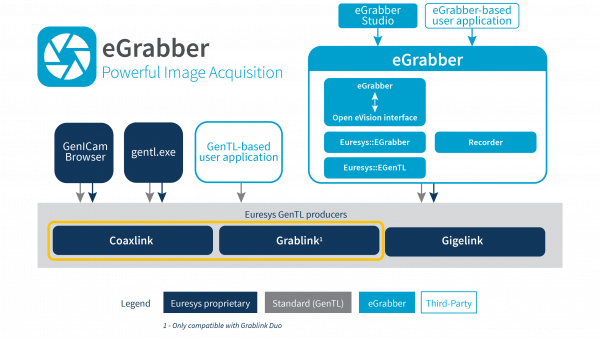

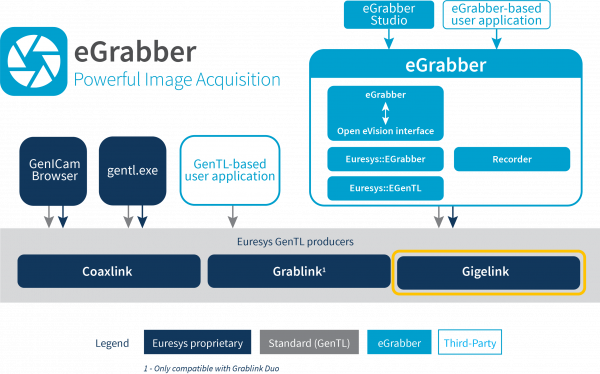

eGrabber is a set of software drivers, tools and applications that enable and simplify the development and debugging of computer vision applications using CoaXPress, Camera Link and GigE Vision cameras.

eGrabber Studio: Powerful Image Acquisition

eGrabber Studio is the evaluation and demonstration application of eGrabber. It allows to test image acquisition with Coaxlink frame grabbers and GigE Vision cameras, check and configure the parameters (GenApi features) of the cameras and frame grabbers and save the acquired images into a file after acquisition. Live histogram and profile display are also available. Designed with a brand-new modern look, eGrabber Studio is compatible with Windows, Linux and macOS.

eGrabber Driver: Coaxlink & Grablink Duo drivers

The eGrabber Driver is a library of classes that provides an easy-to-use programming interface for image acquisition from Coaxlink and Grablink Duo frame grabbers. eGrabber features a high-level, object oriented, user-friendly API compatible with C++, C# and Python.

eGrabber Gigelink: GigE Vision Image Acquisition Library

eGrabber Gigelink is an optional library of eGrabber that provides a universal, hardware-independent access to GigE Vision cameras. With Gigelink, programmers can use the eGrabber concepts, objects, and function calls to acquire images from GigE Vision cameras, in the same way as with CoaXPress cameras (using the Coaxlink cards) and Camera Link cameras (using the Grablink Duo). Gigelink is compatible with GenICam as well as the eGrabber Studio applications.

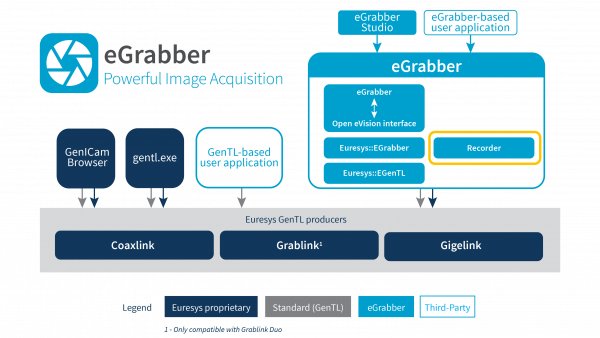

eGrabber Recorder: High-Performance Video Recording Library

eGrabber Recorder is an optional library of eGrabber that offers optimized video recording to hard drives. It is compatible with hard disk drives (HDD) as well as solid state drives (SSD).

eGrabber Playlink: Virtual Frame Grabber & Camera for Machine Vision

eGrabber Playlink is a game-changing feature that allows software developers to test and validate their code without the need for physical acquisition cards and cameras. This virtual frame grabber simulates the image acquisition process, enabling developers to work independently of the machine’s physical environment.

eGrabber Playlink is a standard GenTL (Generic Transport Layer) producer capable of acquiring images recorded by eGrabber Recorder from a real-world acquisition system. It allows developers to focus on the machine vision software application and its validation without worrying about the complexities of image acquisition.

eGrabber Playlink can be used free of charge within eGrabber Studio, which is a great way to learn and evaluate eGrabber Playlink. A “PC4401 eGrabber Recorder and Playlink” license is required when integrating eGrabber Playlink’s API into your own software application.

eGrabber Memento: Event Logging Tool

In high-end inspection machines using vision, the frame grabber is responsible for acquiring images in synchronization with numerous external devices such as motion or lighting controllers, not to mention the camera itself.

Debugging these systems often requires complex equipment, for example, oscilloscopes and logic analyzer, which are used along with software profilers. The problem is even more acute with the latest cameras available, which allow for very fast frame rates exceeding several hundred, even thousand frames per second.

eGrabber Memento has been designed to simplify that process. During the operation, eGrabber Memento records a very detailed log of events related to the camera, the frame grabber and its driver, as well as the host application.