“Garbage in, garbage out” is an old computer science adage that perfectly encapsulates the idea that a computer is only as good as the instructions it’s given. Scientists and researchers use laser beams to measure combustion, airflow, and the chemical properties of a substance, and manufacturers use lasers in 3D printing and product testing. In both cases, the results they get are only as good as the quality and power of the laser beams they’re using to take those measurements.

Laser beams vary in diameter, shape, color/wavelength, and intensity. Researchers use lasers that pulse (blink on and off) and lasers that fire a constant beam of light. Selecting the right type of laser to use for a particular application is critical to obtaining the desired results. That’s why, before a researcher uses a laser to measure something, they measure, or “diagnose,” the laser beam first. Learn more about the importance of laser diagnostics for laser processes.

Knowing why you need a laser and how you’re going to use it will define the type of laser beam diagnostics (or characterization) you need to determine the properties of the laser beam.

Size and Shape

Most people think of laser beams as very thin, fine beams of red light. While laser beams, visible or not, are generally narrow relative to, for example, the beam of light you’d see coming from a flashlight, lasers can vary substantially in diameter (width). They also vary in shape.

Ideally, you want a laser that forms a perfect circle. But many factors can cause distortion in a laser beam’s shape and intensity distribution, from misalignment, damage to the laser cavity, or a fundamental defect originating in the manufacturing process. Checking the shape and energy distribution of the laser beam is important to ensure accurate measurements of whatever object or substance is the target of the laser.

Wavelength

Substances vary in the wavelengths of light they reflect or absorb. When using a laser for chemical analysis, you must know the range of wavelengths you’re expecting to see bounce off materials or show up as black areas where the materials absorb the light. This expectation influences the choice of a laser based on the composition of the beam measured in wavelengths of light.

Lasers can be made up of visible, infrared, or ultraviolet light. Discoveries happen when you see something you didn’t expect on an image or wavelength spectrum captured when laser light shines on a substance.

Propagation and Focus

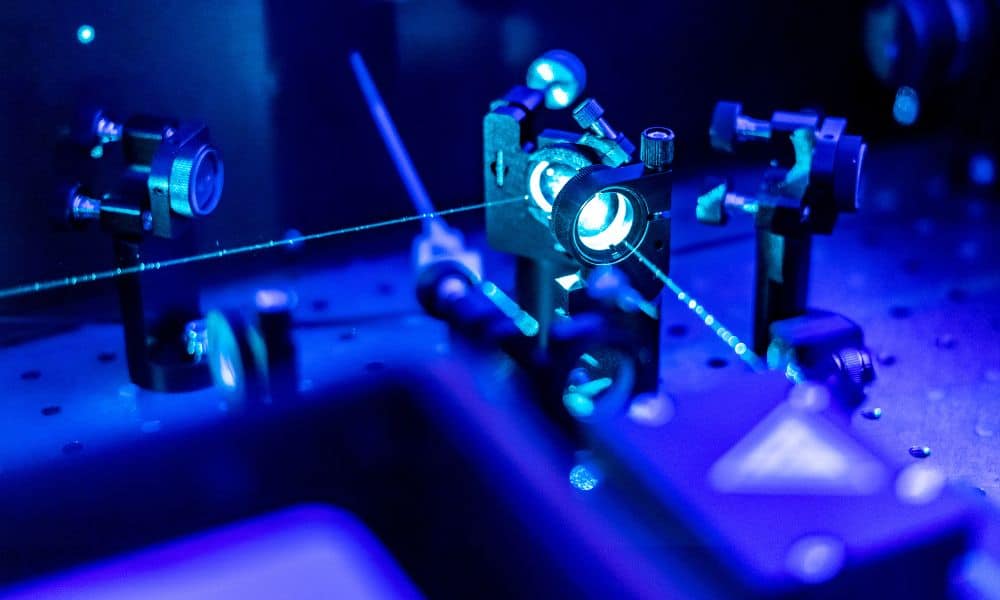

The intensity or saturation of a laser beam changes as it travels through space. First, to aim a laser at an object, the light must bounce off several mirrors. Then the light travels through the air or, in some scientific applications, through a vacuum, to hit its target. Along the way, the laser can attenuate, meaning there’s a decrease in laser intensity, and the light spreads out a little as it travels toward its target. The measurement of changes in a laser beam, when focused by a lens, tells a lot about its overall quality and is an important parameter called its propagation.

Instruments called laser beam profilers can measure the intensity of a laser, its size, shape, and propagation, as well as its focus at the point it hits its target. Different types of profilers are best for different purposes.

For 3D printing, for example, a focus beam profiler, or FBP, measures the intensity, shape, and radius of a laser beam near its focal point. This is important for accurate scanning of the shape of an object to be printed or to direct the operation of the printer to produce the desired object.

In a scientific or research and development lab, a tabletop M2 instrument is the better choice. This type of laser beam profiler measures the degree to which a laser beam diverges from the point of generation to the target it’s focused on against an ideal called a Gaussian beam. The less divergence, the more refined the focus of the beam can be.

The Effect of Time

Typical images of goggle-wearing researchers observing a laser beam in a lab show a continuous beam of light. But many scientific and research labs use a pulsed laser beam, which produces a very short burst of powerful laser light. Using a pulsed beam allows researchers to measure the temporal effect of laser energy on a substance, including how long the atomic particles that make up the substance remain excited by the energy the light exerts on them.

A measure of changes in the intensity of pulsed laser light over minuscule amounts of time is a critical factor in calculating the response to that light. Researchers measure the duration of ultrafast light pulses using autocorrelators. and in other instances, they use frequency-resolved optical gating (FROG) technology or chirp, which measures the distribution of wavelengths over the duration of a pulse when using an ultrafast pulsed laser.

Pulsed lasers have practical uses, as in welding, where short bursts of extremely intense laser light produce better results. Spot welding is a good application for pulsed laser welding because the very short bursts of laser energy both overcome reflectivity and reduce heat (because of the short duration), making these types of welders good for heat-sensitive materials.

Whether you use 3D printing in manufacturing or prototyping, or you’re a researcher working at a university, pharmaceutical, or industrial lab, you need reliable laser beam diagnostic equipment. You can find it here at Axiom Optics. We offer a variety of laser instrumentation devices including UV, VIS, and IR beam profilers; InGaAs beam profilers for wavelengths that silicon-based detectors cannot record; and autocorrelators and FROG systems for pulsed lasers. Before you begin using lasers in research, quality control, or manufacturing, contact Axiom to find the right instrument to perform important laser diagnostics for the laser process you intend to use.